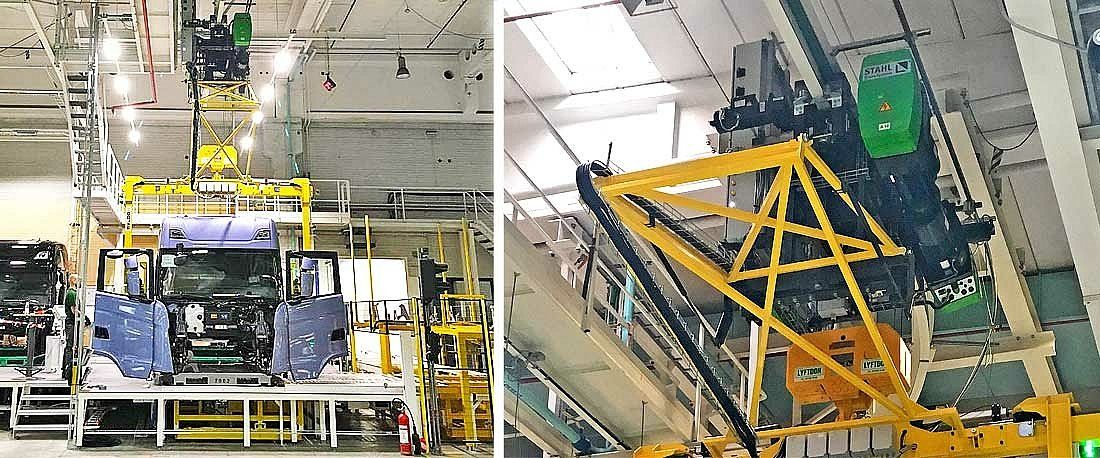

Twin Drive Concept

Twice As Safe And Reliable

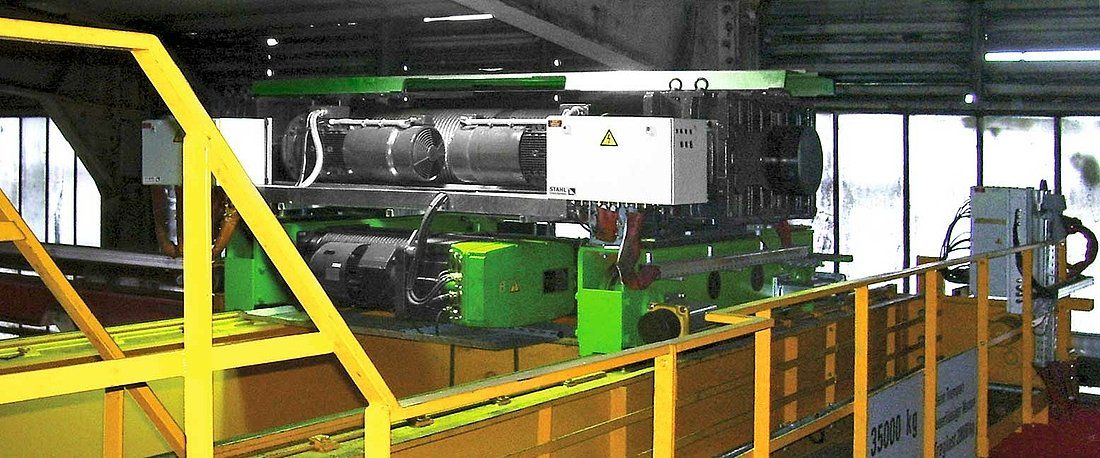

The TDC Twin Drive Concept is the uncompromising solution for hoists according to DIN EN 14492-2, Annex B. TDC wire rope hoists are suitable for the transport of molten metals and for use in high-risk applications: e.g. acids, alkalis, gases or transport through gas and acid pipelines. They are equipped as standard with two redundant motor/gearbox units.

Generally, both motors are actuated synchronously. Each of the brakes mounted on the two motors are designed such that they are able to brake or hold the load on their own in an emergency. Both brakes are actuated together and serve as operating and holding brake.

All drives in Twin Drive Concept wire rope hoists are monitored by condition monitoring systems from STAHL CraneSystems.

- Fulfils requirements of industry standard EN 14492-2

- TDC prevents the load dropping even if the gear should break

- Two synchronously controlled hoist motors and brakes

- Continuous monitoring of brakes, drives and load

- Twin gear and braking safety

- Two brakes with manual release for emergency lowering

- Robust, fully enclosed system

- Up to 60 % higher load capacity when not transporting molten metals

Slide title

In the case of a problem (e.g. broken gearbox) the load can be lowered with the two manual release brakes. ›Recovery of the load‹ is then no longer necessary.

Button

Slide title

When transporting non-molten materials, the wire rope hoist can be loaded with a 60 % higher weight.

Button

Slide title

In the case of an overload a separate load monitoring device switches off the motors automatically. The robust system is completely encapsulated and thus protected against dust and moisture.

Button

Download

Brochure

The SH wire rope hoist

Useful links

Contact info

Phone: +27 (0)83 326 8728

Email: sales@stahlcranes.co.za

Address: 34 Potgieter steet , Alrode ,Alberton

Join the Newsletter

We will get back to you as soon as possible

Please try again later

All Rights Reserved | Stahl Cranes | Privacy Policy | She Policy