Liquid Nitrogen Gas (LNG)

Wire Rope Hoists

LNG Hoists For Liquefied Gas Trains And Terminals

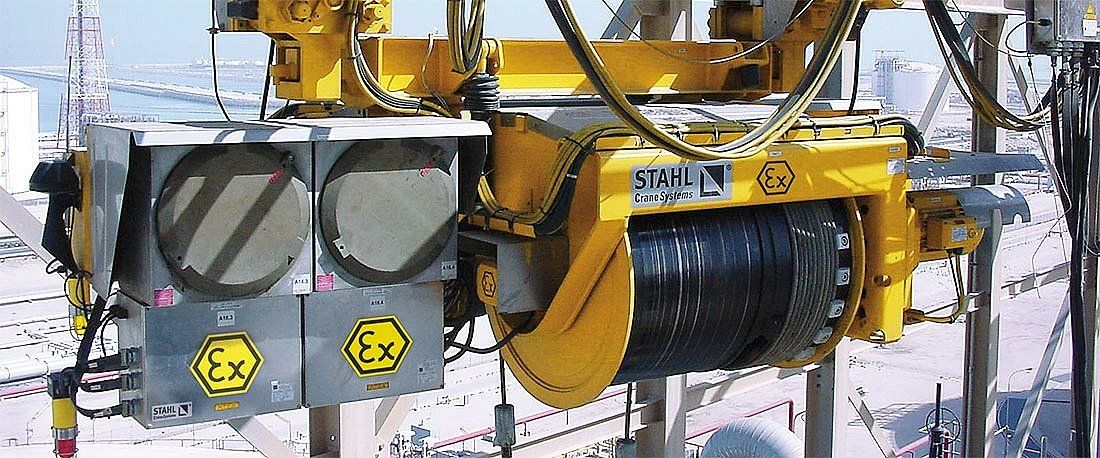

The LNG wire rope hoists from STAHL CraneSystems are designed specifically for maintenance work on liquefied natural gas (LNG) tanks. Due to their high-quality components, robust construction, corrosion-resistant finishes and many other features, they are ideally suited for use in coastal regions with demanding climatic conditions. The pumps, which pump the cold liquefied natural gas (–164 °C to –161 °C) in a pipe system, must be lifted out of the approximately 70 metre high tanks into the open for maintenance work up to five times a year. In view of the extreme conditions in the tank, special ropes, which are fastened permanently to the liquefied natural gas pump and therefore spend their lives in the tank, are needed for this. When maintenance work needs to be carried out, these ropes are fastened to the rope drum and hoist with quick fasteners.

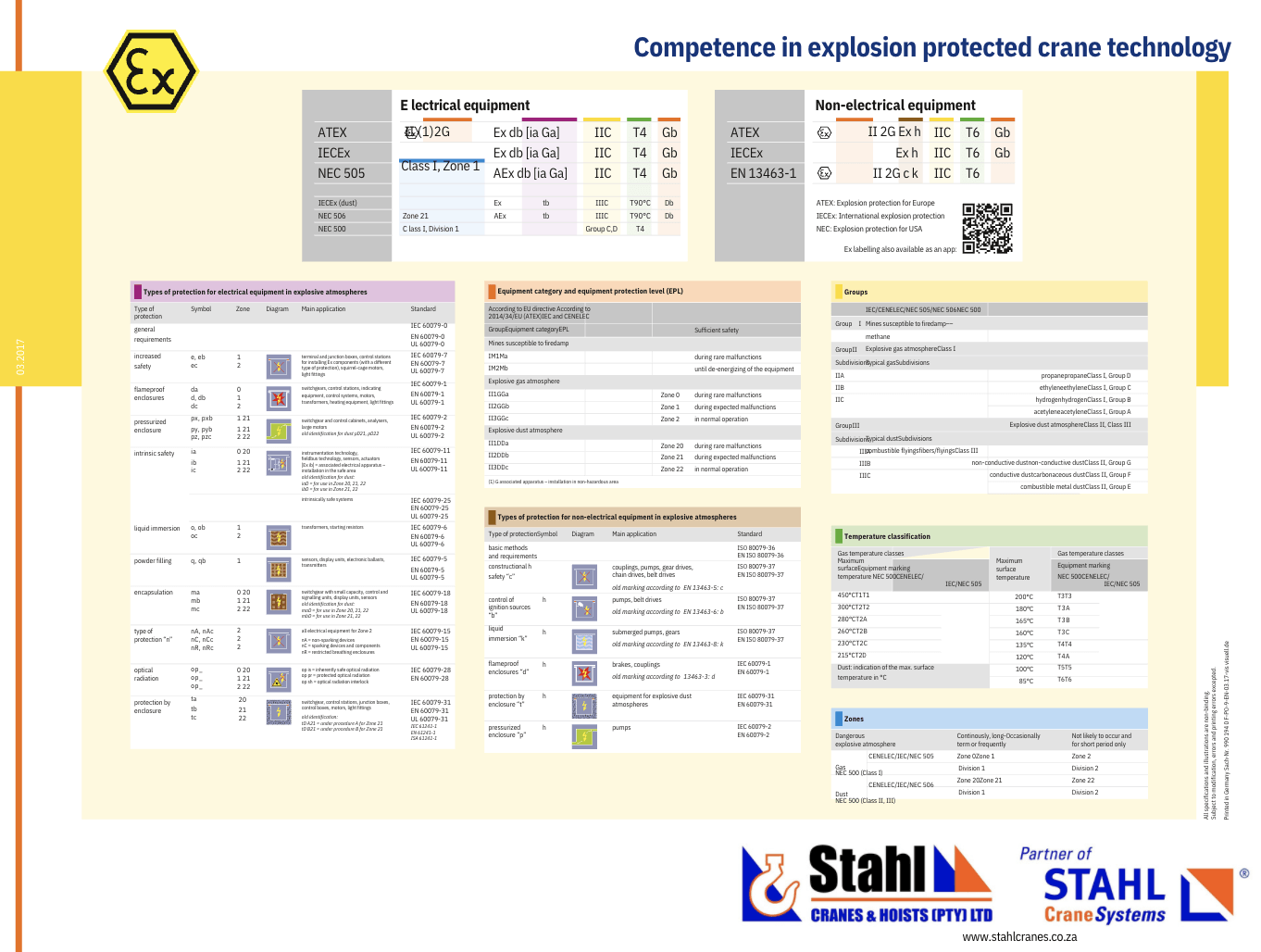

The experts in our engineering department develop these special hoists according to individual requirements, specifications, quality standards and national regulations. The projects are implemented economically, effectively and in constant high quality. This includes compliance with all global regulations and standards, implementation of all international certifications and customer-specific documentation.

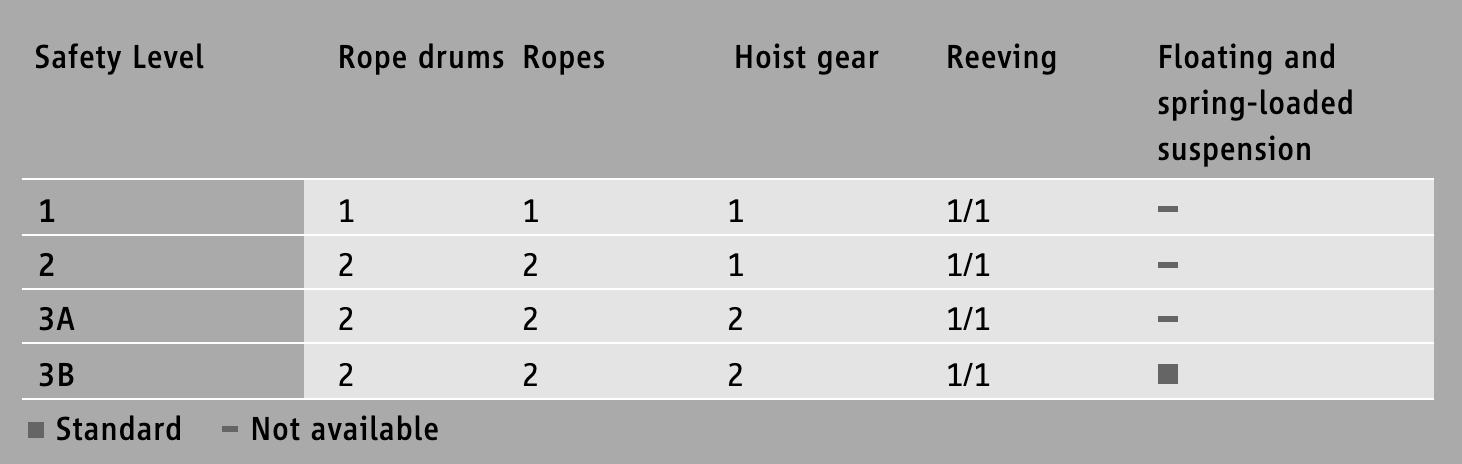

The LNG hoists from STAHL CraneSystems are offered in four safety levels. The LNG wire rope hoists from STAHL CraneSystems in level 3B are currently regarded as the safest explosion-proof hoists available on the market.

- Sophisticated engineering ideally adapted to your project

- Technically mature, using fieldproven standard components

- International specialist for explosion-protected hoist and crane technology

- Our own production with certified quality assurance

- All customised solutions certified to ATEX directives or IECEx regulations

- Partner for official international procedures

- Full documentation

Slide title

The LNG wire rope hoist in Safety Level 3A is equipped with two brakes, two gearboxes and two ropes for double safety.

Button

Slide title

The SH 50 Ex wire rope hoist is protected against dust, sand, heat, cold and salty sea air by special coatings.

Button

Slide title

LNG hoist with Safety Level 2

Button

Slide title

LNG hoist with Safety Level 3A

Button

Slide title

The slewing crane on the LNG tank positions the hook of the manual chain hoist perfectly above the pump port.

Button

Slide title

LNG hoist with Safety Level 1

Button

Slide title

LNG hoist with Safety Level 3B

Button

Slide title

The experts in our engineering department develop these customised hoists for every crane manufacturer and EPC contractor to meet their individual requirements, specifications, quality standards and national regulations.

Button

Slide title

Housings protect the SH LNG wire rope hoists from the weather during long stop periods.

Button

Slide title

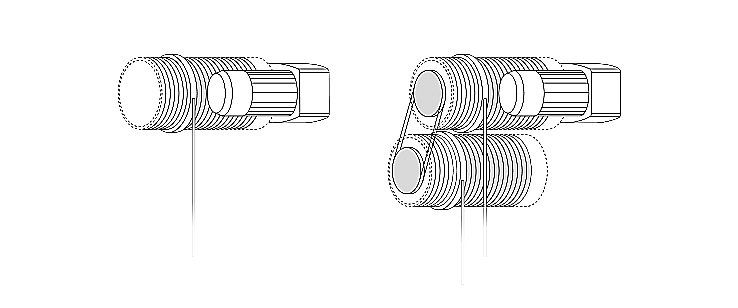

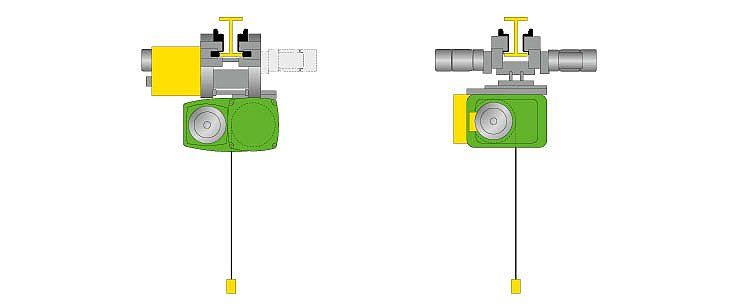

Safety Level 1 and 2

Safety Level 1 with increased safety

Safety Level 2 with two rope drums running in parallel

Button

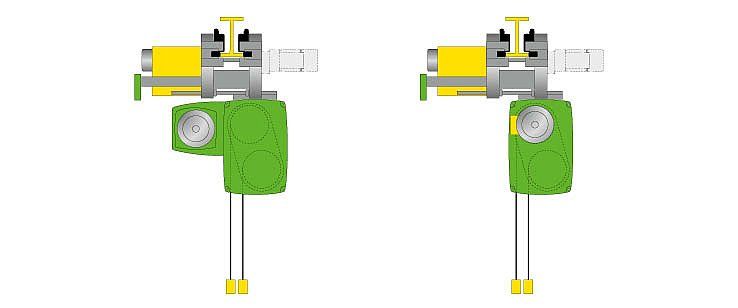

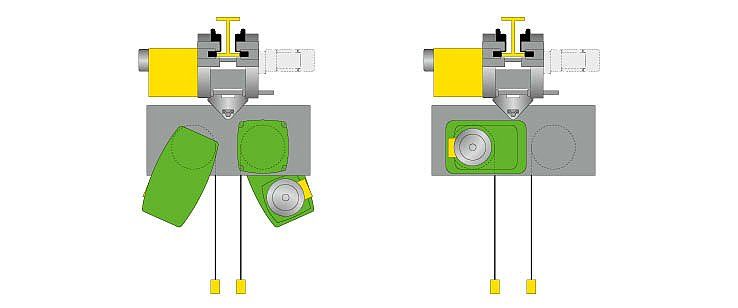

Slide title

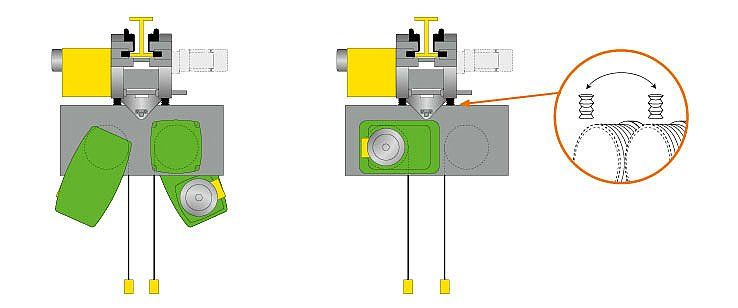

Safety Level 3A and 3B

Safety Level 3A with redundant hoist

Safety Level 3B with additional floating and dampened suspension

Button

Slide title

Safety Level 1

As a basic principle, LNG hoists are custom built to the individual specifications and requirements provided by systems builders and EPC contractors. Safety Level 1, the lowest level, employs explosion-protected hoists from STAHL CraneSystems’ SH wire rope hoist programme or AS wire rope hoist programme, specifically designed for routine maintenance work on LNG trains. There is only one motor, hoist gear and brake. The modular principle enables various customer requirements to be met.

Button

Slide title

Safety Level 2

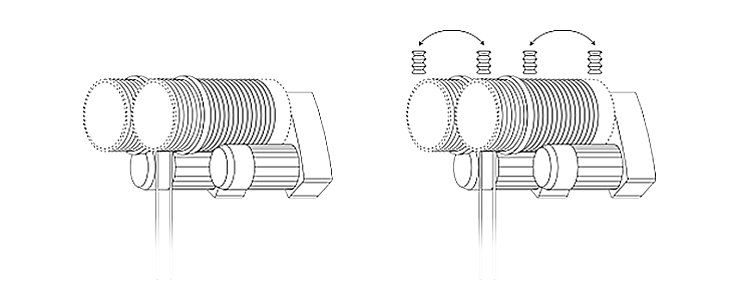

In Safety Level 2, two rope drums from the SH wire rope hoist programme, permanently connected by a chain, are driven by one motor.

As an option, a fast action lock can be used to exchange the standard wire rope and the rope of the liquefied gas pump. The LNG pump’s ropes can be taken up on one drum or on both drums in parallel as required. There is only one motor, hoist gear and brake. The modular principle enables various customer requirements to be met.

Button

Slide title

Safety Level 3A

The LNG hoist in Safety Level 3A is equipped with two separately driven motor-gear units running parallel, two rope drums and two brakes. The brakes are designed so that each one individually is able to brake or hold the load in an emergency. The brakes are synchronously controlled and act as service and holding brakes. The off-standard wire ropes permanently connected to the pump are attached to the rope drum of the LNG hoist by an optional fast action lock. Generally, lifting is performed by one load-bearing rope, the second rope runs parallel as a dead rope without load. In the unlikely event that one of the ropes should break, the second hoist can take over the load and continue lifting.

Button

Slide title

Safety Level 3B

LNG wire rope hoists in Safety Level 3B are masterpieces of STAHL CraneSystems’ engineering and are regarded as the safest, mosttechnically mature hoists in the world. As with the LNG hoists in Safety Level 3A, their construction is fully redundant. Increased safety is guaranteed by the additional floating and spring-loaded suspension. Only one rope acts as lifting rope when lifting the pump. The second hoist runs in parallel with a dead rope as backup. If the load rope should break during lifting, the second hoist takes over. However in Safety Level 3B, the hoist’s floating and spring-loaded suspension absorbs the impact of the abrupt load change without jolting and ensures that the load’s centre of gravity stays centred under the hoist. Lifting can continue without disruption and without damaging the valuable pump or any part of the system.

Button

Download

Brochure

Expertise in explosion protection

Useful links

Contact info

Phone: +27 (0)83 326 8728

Email: sales@stahlcranes.co.za

Address: 34 Potgieter steet , Alrode ,Alberton

Join the Newsletter

We will get back to you as soon as possible

Please try again later

All Rights Reserved | Stahl Cranes | Privacy Policy | She Policy