AS 7 Wire Rope Hoist

The Compact Powerhouse

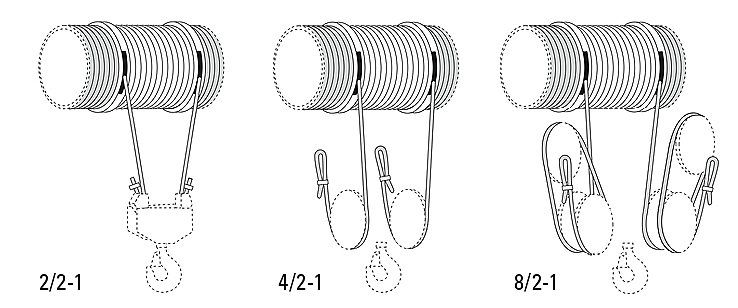

The AS 7 wire rope hoist programme is the innovative classic in hoisting and crane technology worldwide. The modular system enables innumerable combinations of the subassemblies for customised solutions.

The AS 7 series is designed in two variants for the upper lifting capacity range to 125,000 kg. The ASR 7 wire rope hoist is the reduced version of the tried-and-tested AS 7 wire rope hoist. It is designed for a safe working load range from 20,000 kg to 32,000 kg and closes the gap between efficient use of the SH wire rope hoist programme and the AS 7 wire rope hoist programme.

The revised design as twin hoist covers the same fields of application as the AS 7 wire rope hoist, albeit with higher lifting capacities, greater lifting heights and faster lifting movements. One important safety feature of the AS 7 wire rope hoist when designed as twin hoist is its exact positioning of the load. As the rope of the twin hoist runs in opposite directions simultaneously, the load is lifted and lowered without any sideways movement of the hook.

If wanted, the complete wire rope hoist programme is also available in explosion-proof design for Zone 1, Zone 2, Zone 21 or Zone 22.

- Two designs for load capacities up to 125,000 kg

- Reduced-size ASR 7 for a safe working load range from 20,000 kg to 32,000 kg, with larger height of lift, standard with exact load measurement at the rope anchorage (entry-level model)

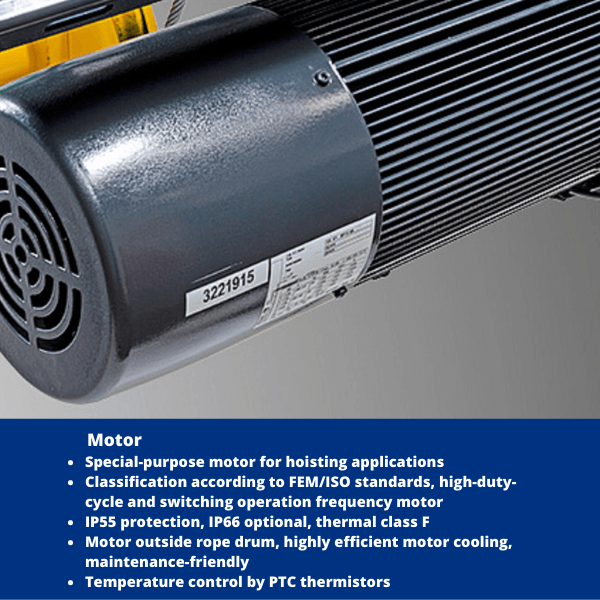

- Innovative drive technology with cylindrical rotor motor with monodisc spring-loaded brake

- Stationary version or double rail crab for systems and crane building, optionally available as underslung trolley or articulated trolley

- Compact construction and low approach dimensions

- Higher load capacity, hoisting speed and lifting height as twin hoist

- Largely maintenance-free, low wear, long service life according to FEM/ISO standards

- Optionally available in explosion-proof design according to ATEX, IECEx

Slide title

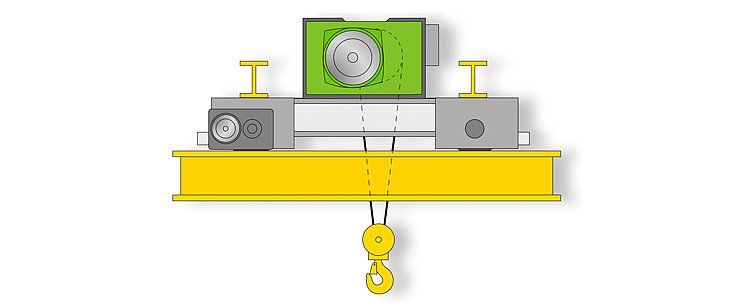

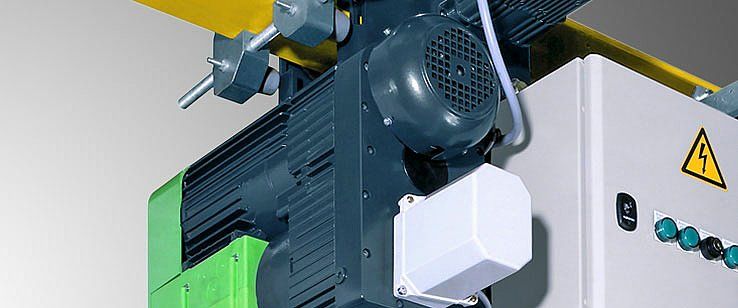

In spite of its high lifting capacity, the AS 7 wire rope hoist with its double rail crab is surprisingly compact. The AS 7 is particularly suitable for high safe working loads to 80,000 kg or crane systems requiring a high ISO classification according to FEM/ISO standards

Button

Slide title

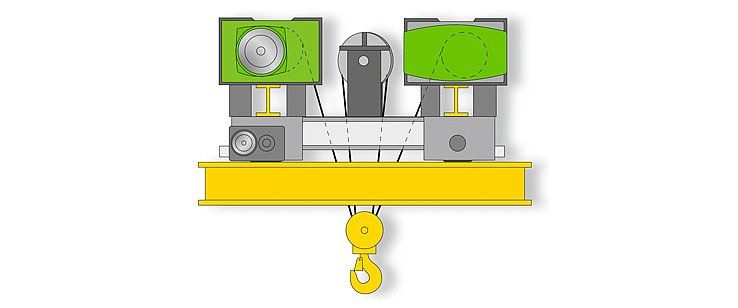

As twin hoist, the AS 7 ZW wire rope hoist enables a lifting capacity to 125,000 kg, higher lifting speeds and exact positioning without sideways movement of the hook.

Button

Slide title

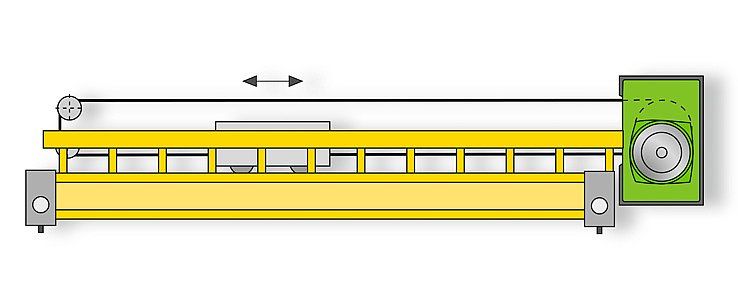

The AS 7 wire rope hoist can also be operated as custom solution with a monorail trolley underneath the crane bridge.

Button

Slide title

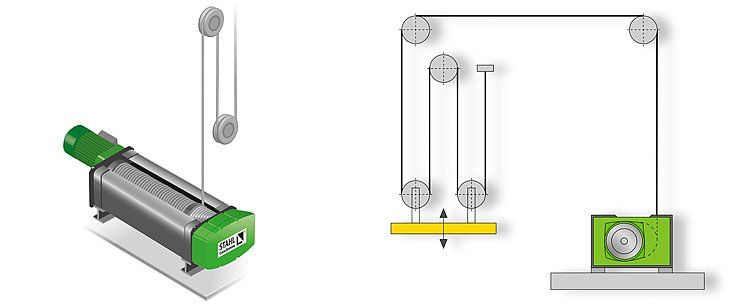

The AS 7 wire rope hoist can be coupled to another type of wire rope hoist like, for example, an SH wire rope hoist for synchronous operation in tandem mode per radio remote control.

Button

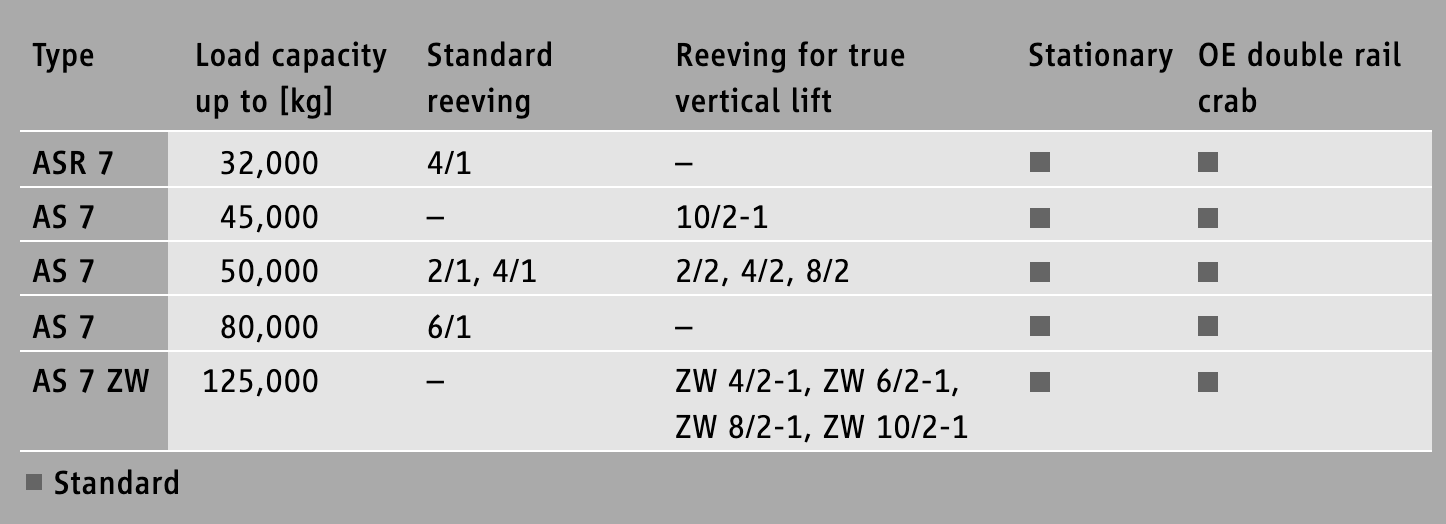

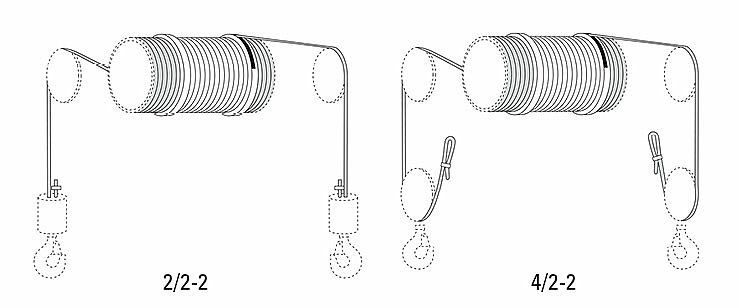

Models

The different models and trolley variants allow not only a wide variety of uses, but also very individualised solutions tailored to specific requirements.

Slide title

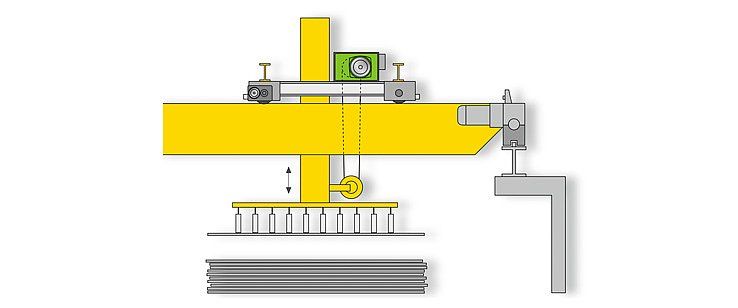

Stationary model

The AS 7 wire rope hoist can be used as stationary hoisting or towing equipment, for example in systems manufacture. Depending on the application, the rope lead-off angle, the attachment of the hoist and the mounting position of the hoist motor can be varied.

Button

Slide title

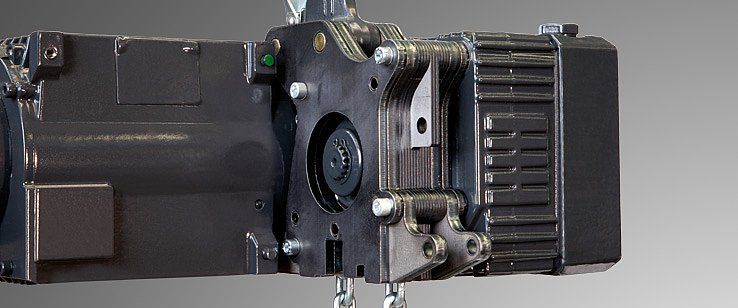

OE double rail crab

The OE double rail crab is intended for use on double girder overhead travelling cranes. The extremely compact construction makes very low approach and headroom dimensions possible and the available space can thus be used to the full. The double rail crab is available with various track gauges for the whole load capacity range.

Button

Slide title

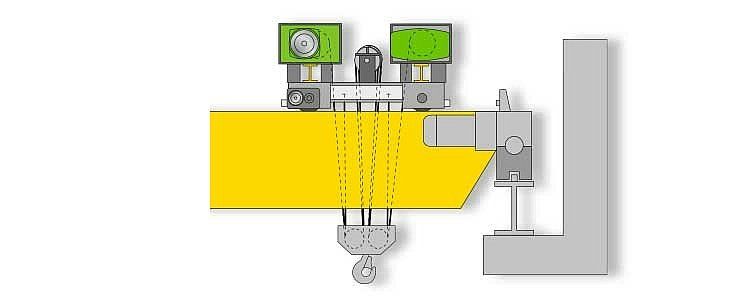

Twin hoist

The AS 7 ZW wire rope hoist can also be used as stationary hoisting equipment or with the OE double rail crab.

Button

Slide title

Horizontal towing equipment in systems building

The AS 7 wire rope hoist used as horizontal towing equipment in systems manufacture

Button

Slide title

Vertical towing equipment in systems building

The frequency controlled AS 7 wire rope hoist used bolted to the floor as vertical towing equipment in systems manufacture.

Button

Slide title

Guided load lifting

The AS 7 wire rope hoist with guided load pick-up.

Button

Slide title

Double rail crab

The AS 7 ZW wire rope hoist is mainly used with a double rail crab on double girder overhead travelling cranes.

Button

Slide title

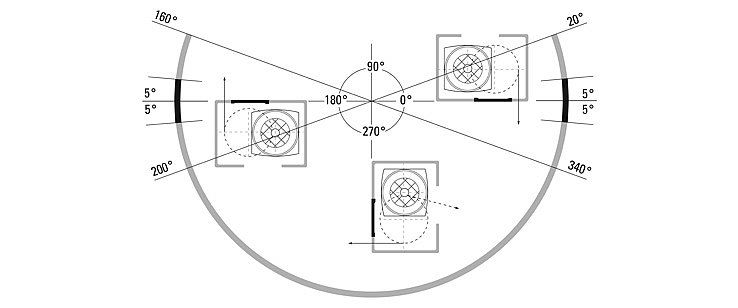

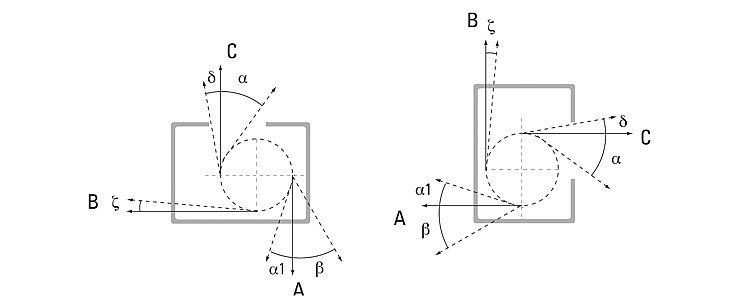

Angle of installation

The AS 7 wire rope hoist can be mounted in various angle ranges. For rope drives with bottom hook block the wire rope hoist must always be installed with its longitudinal axis horizontal.

Button

Slide title

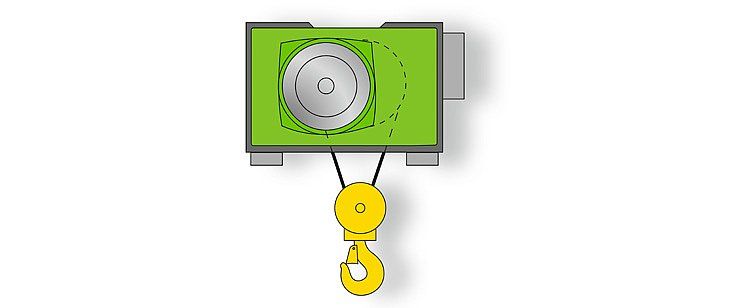

Single-grooved rope drum (Standard reeving)

The model with single-grooved rope drum is used for stationary hoisting or towing equipment or combined with various travel carriage variants.

Button

Slide title

Double-grooved rope drum (True vertical lift)

If true vertical lift is required, we recommend this model with double-grooved rope drum (right-/left-hand thread). This version can be used both in stationary form or with travel carriages.

Button

Slide title

Double-grooved rope drum (Reeving for multiple load pick-up points)

The model with double-grooved rope drum (right-/left-hand thread) is used for many lifting and towing tasks where the load must be picked up at more than one point and true vertical lift is required.

Button

Slide title

Twin hoist (Reeving for true vertical lift)

Independent of the grooving of the rope drum, stable guiding of the hook and precise positioning of the load are guaranteed.

Button

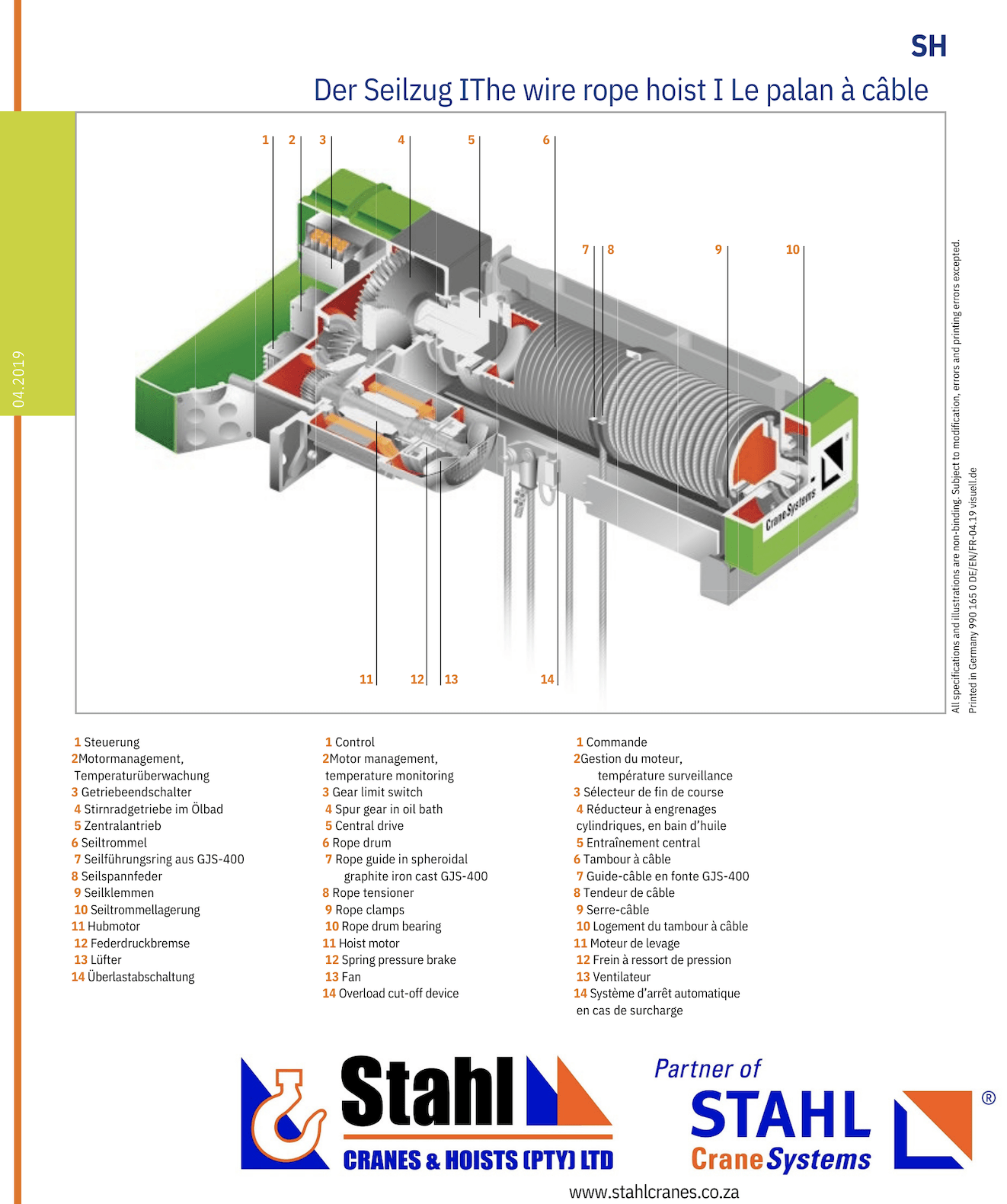

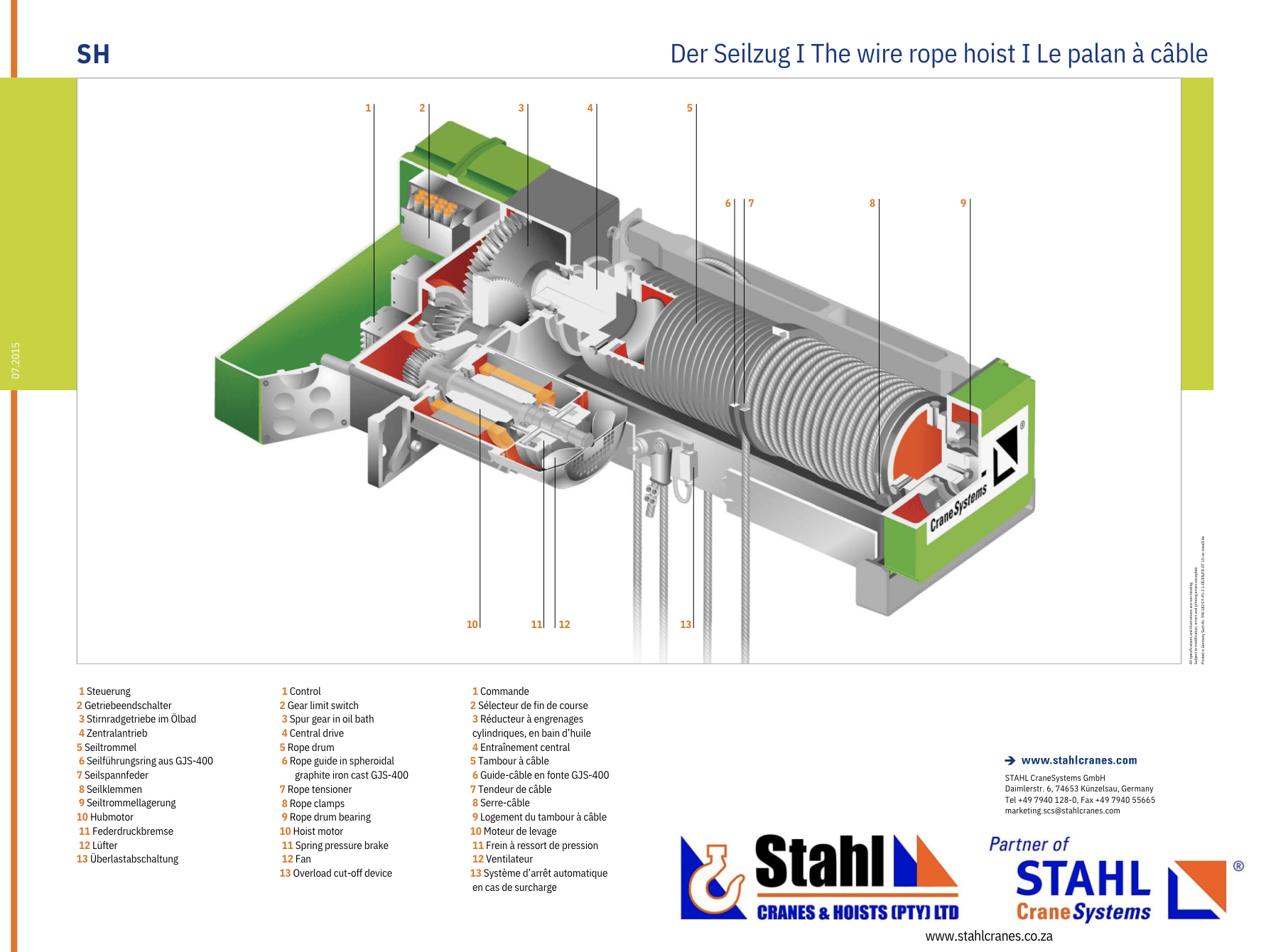

Technology

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Options and features

Although they are already first-class in their standard design, you can make the hoists even safer, more economical and more convenient with a range of mechanical, electrical and electronic options. They simultaneously improve performance, prolong service life and make it possible to adapt the hoist individually to specific requirements.

Here are some of the options frequently used.

Slide title

Control pendant

Robust control pendant with EMERGENCY STOP palm button and control cable

All switching elements for hoist, cross, and long travel are 2-step

IP65 protection

Additional buttons, such as horn activation, can be easily fitted

Button

Slide title

Radio remote control units

Flex-Wave pushbutton unit with protective cover and carry strap

VUE pushbutton units with feedback display

MLTX2 joystick transmitter with controller and carry strap

Optional battery chargers with standard rechargeable batteries

Robust, fibre-reinforced plastic housing, IP66 protection

Frequency ranges 433, 863 or 2,400 kHz

Also available in explosion-proof version

Other radio remote control units optionally available on request

Button

Slide title

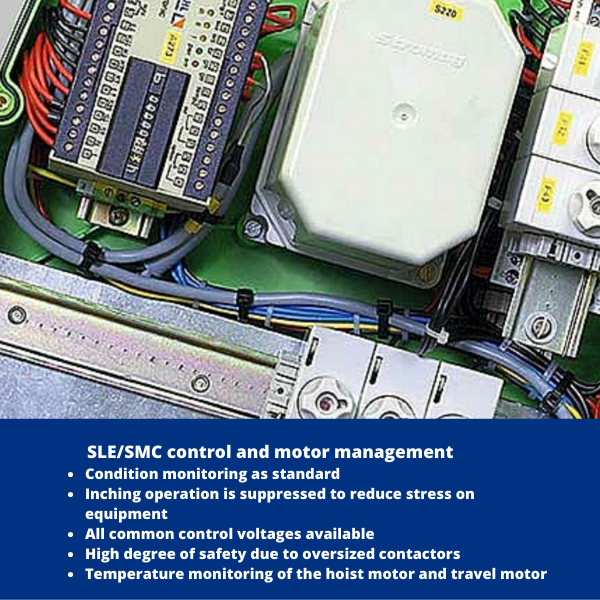

SMC Multicontroller

Continuous load monitoring by overload cut-off even if hoist is idling

Overload protection with ALC automatic load control

Load spectrum memory for load-related operating time summation

Operating data registration, e.g. operating hours, load spectrum, motor switching operations and load cycles

Data exchange with PC possible

Button

Slide title

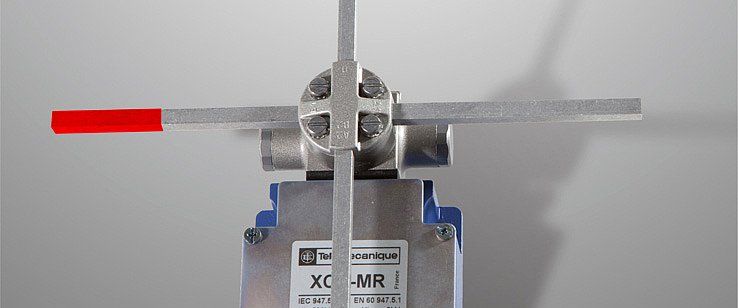

Travel limit switch

Travel limit switch on crab available as option

Limiting for both directions of travel

Switchover from “fast/slow” (predisconnect)

Switch contacts designed for control current

IP66 protection

Button

Slide title

Operational hoist limit switch

Two versions are possible: cut-off in top hook position or cut-off in top and bottom hook position (stationary, push trolley, electric trolley)

Activated by the bottom hook block

Button

Slide title

Gear-type limit switch

Various functions possible: e. g. routine operational cut-off in highest or lowest hook position or switching from “fast” to “slow” before the stops

IP55 protection, optionally IP66

Button

Slide title

Spring-steel chain guide

Heavy high-tensile chain guide for rugged use

Enclosed chain guide

Extremely wear-resistant case-hardened chain sprocket

Button

Slide title

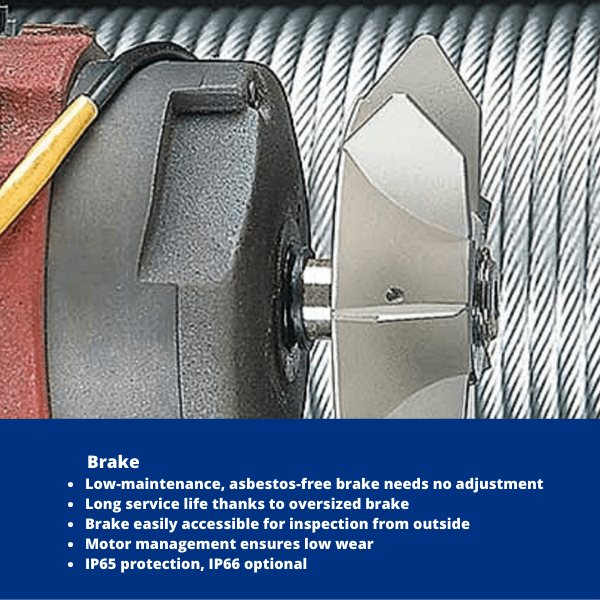

Bypass brake

Second brake for increased safety

Identically dimensioned

Second brake acts in force transmission directly on the load, i. e. bypassed the slipping clutch

As an alternative to the bypass brake, a second hoist motor brake is available

Button

Slide title

Write your caption hereLoad display

SLD four-digit 7-segment load display, large format, luminous red

Available with various interfaces including CAN

Choice of 100 or 150 mm digit height

Combinable with the hoist’s overload sensor and the SMC multicontroller available as an option, no additional fixtures or load attachment devices are required, the headroom of the hoist remains unchanged

Button

Slide title

FMD1 slipping clutch test device

Robust full metal design

Modern electronic test apparatus with field-proven sensor technology, high degree of accuracy ± 2 %

Test range up to 4,000 kg on one chain fall, suitable for chains up to 11.3 mm link thickness

Optionally available for STD and STK

Protector for evaluation device and internal test program

Simple intuitive handling

Button

Download

Brochure

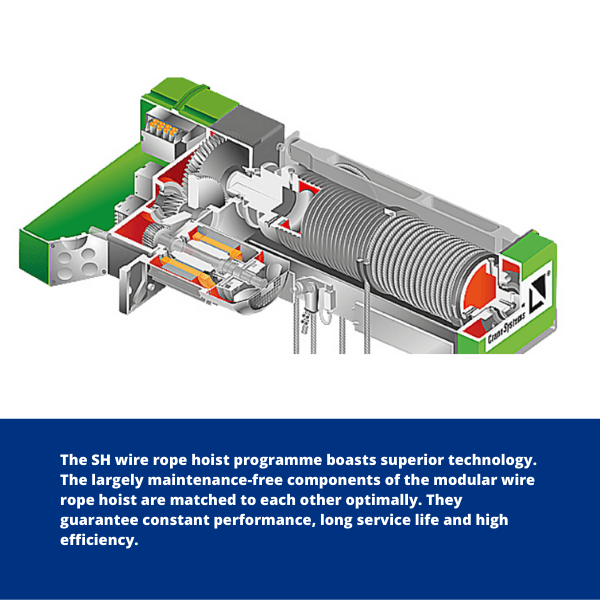

The SH wire rope hoist

Poster

The wire rope hoist SH

Useful links

Contact info

Phone: +27 (0)83 326 8728

Email: sales@stahlcranes.co.za

Address: 34 Potgieter steet , Alrode ,Alberton

Join the Newsletter

We will get back to you as soon as possible

Please try again later

All Rights Reserved | Stahl Cranes | Privacy Policy | She Policy