Custom Solutions

Sophisticated Technology – Customised And Perfect

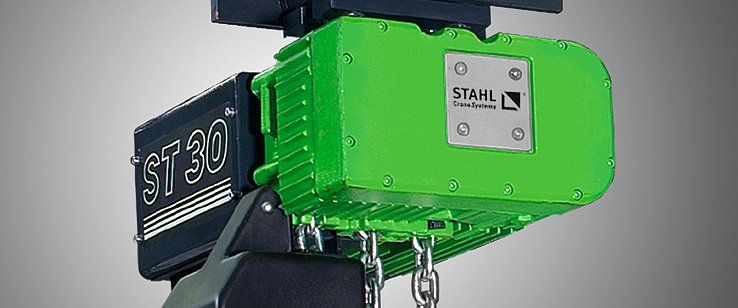

System solutions adapted individually to specific custom solutions are STAHL CraneSystems’ forte. Virtually no other manufacturer of hoisting and crane technology offers such a variety of custom solutions with such quality and such efficiency. We develop the best technical solution for every requirement. The modular ST chain hoist programme forms the basis for the wide variety of versions. For example, dual chain hoists, multiple reeved chain hoists, STB Big Bag version and coupled chain hoists for four-point load attachment.

The chain hoists are also available in explosion-proof design for Zone 1, Zone 21 and Zone 22.

- Optimally matched to your project

- Every hoist is the result of over 140 years of experience and expertise

- Short development time

- Cost-effective thanks to modular system

- Technically mature thanks to the use of field-proven standard components

- High quality and reliability ensured by in-house production

- All customised solutions are available as an option in explosion protected design complying with ATEX and IECEx.

Slide title

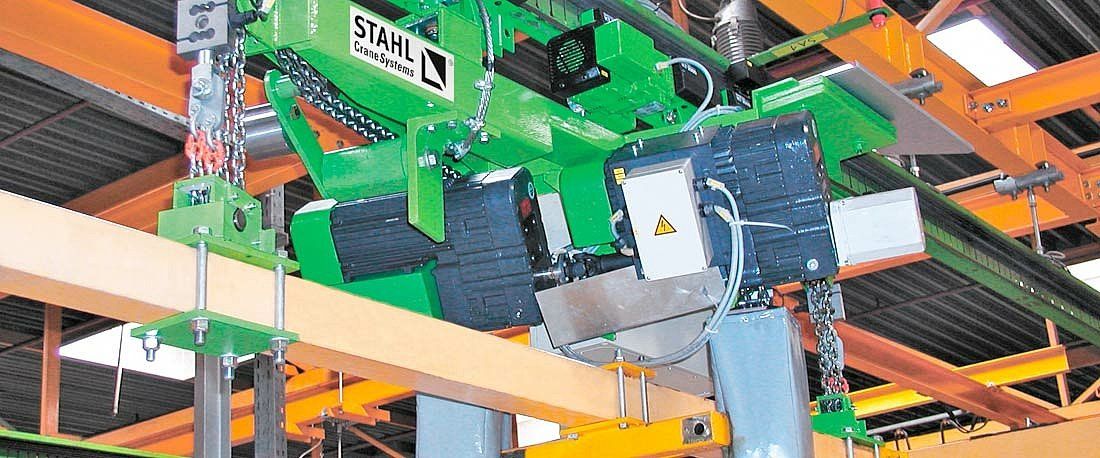

A special crane with explosion-proof ST chain hoists is used in a powder-coating line. The rails are suspended with specially made bolts.

Button

Slide title

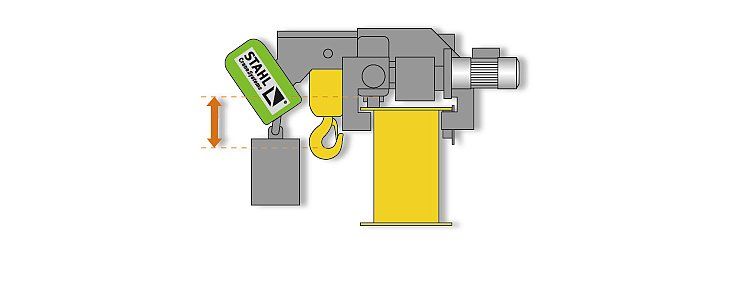

Redundant implementation of the brake and chain drive improves safety when working on and under the suspended load.

Button

Slide title

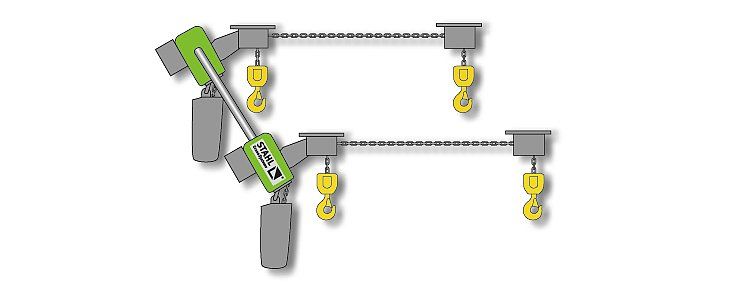

Two coupled STD dual chain hoists with four synchronised load hooks enable low-swing transport of heavy long material.

Button

Slide title

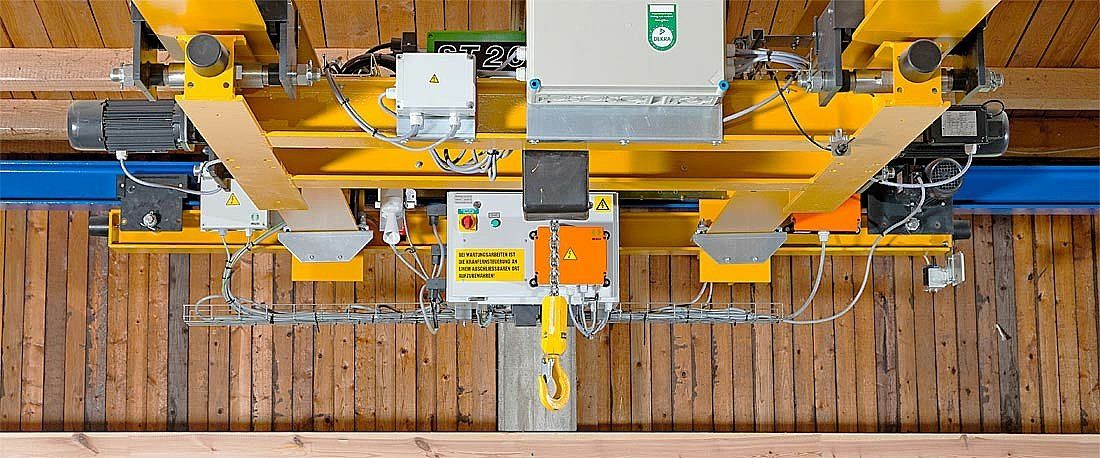

A custom two-beam suspension crane with raised crane bridge and raised ST chain hoist enables an extremely short headroom of 58 cm.

Button

Models

The different models and trolley variants allow not only a wide variety of uses, but also very individualised solutions tailored to specific requirements.

Slide title

Coupled chain hoists for 4-point load attachment

Button

Slide title

Custom cantilever crab solution

Button

Slide title

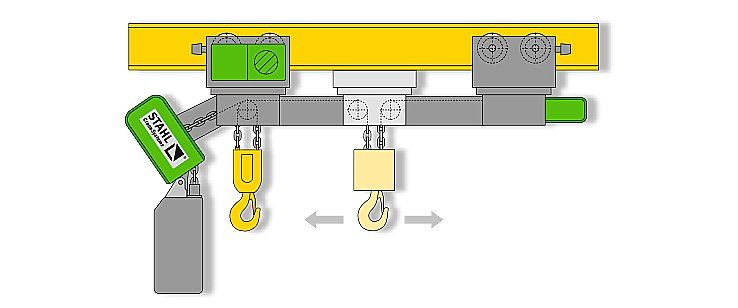

The STD Vario dual chain hoist

The distance between hooks is electrically adjustable and can be individually adapted to loads of different lengths. Both hooks run absolutely in synch. The load hooks cannot be accidentally shifted during lifting or travel.

Button

Technology

Slide title

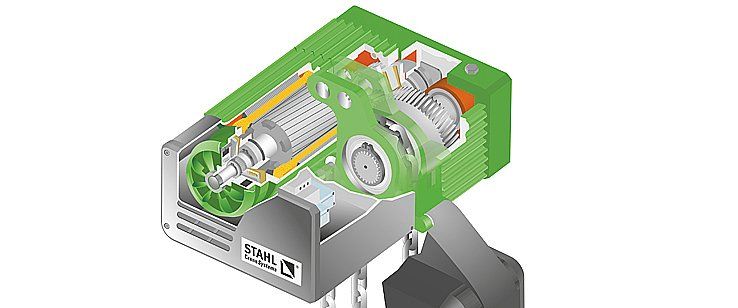

The ST chain hoist programme boasts superior technology. The low-maintenance components of the modular chain hoist are optimally matched to each other. They guarantee constant performance, long service life and high efficiency.

Button

Slide title

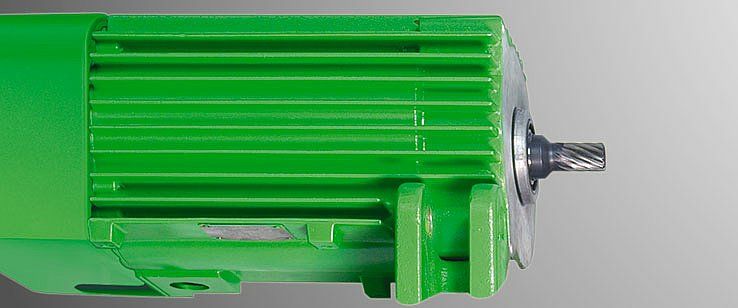

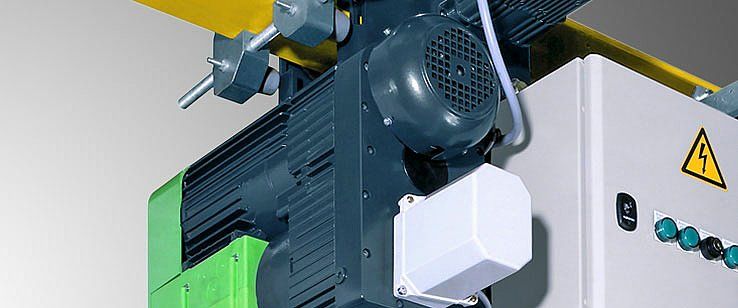

Motor

High ISO classification according to FEM/ISO standards

Powerful motors with high duty cycle and number of switching operations

Standard fan cooling

Single-speed and frequency-controlled versions available as options

Optional temperature control by thermistor

Button

Slide title

Brake

Low-maintenance, asbestos-free electromagnetic disc brake

Oversized braking torque

Long service life, brake pad status can be checked and measured

Brake completely enclosed, protected from humidity, vapours and dusts from the exterior; ensuring long-term reliable operation

Button

Slide title

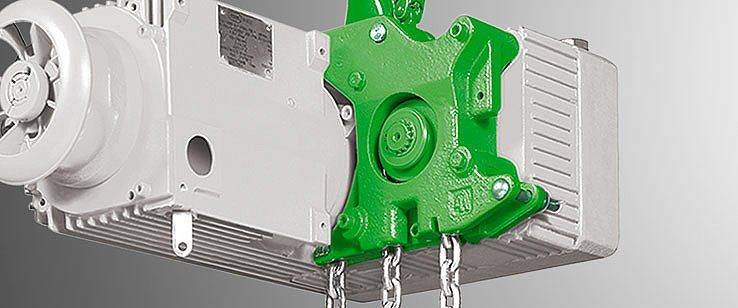

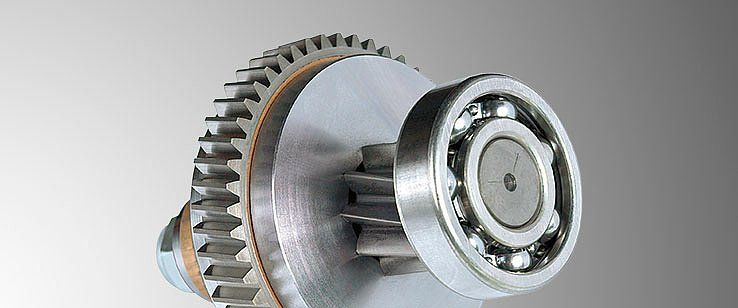

Chain drive

Innovative patented chain drive

Anchorage and load-bearing components are directly integrated into the high-tensile grey cast iron

Simple inspection and replacement of the chain sprocket thanks to over-mounted shaft bearing

Enclosed chain guide

Reliable functioning even in demanding applications

Wear-resistant case-hardened chain sprocket in conjunction with optimised return sheaves; ensuring low wear on the chain

Button

Slide title

Standard control

All customary connecting and control voltages are available

Plug connection of control pendant and travel motor

Clear arrangement of contactors

As an option, available with direct control

As an option, available without control pendant and/or contactor control

Button

Slide title

Paint

Standard paint treatment as per RAL 6018 yellow-green and RAL 7021 greyish black

High-quality primer and top coats for standard applications

Off-standard paint treatment for outdoor use or corrosive ambient conditions

Other colours per RAL chart optionally available

Button

Slide title

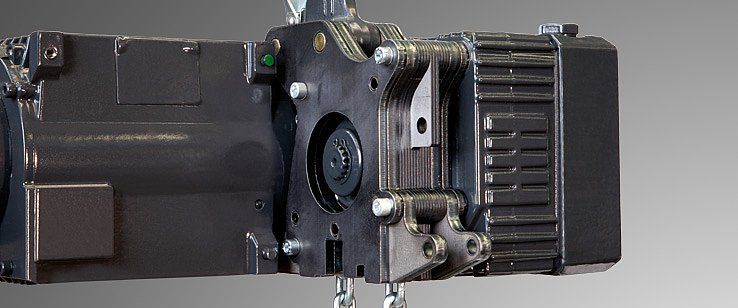

Overload slipping clutch and gear

The slipping clutch of the ST 10 to ST 60 is located in the oil bath.

Easily adjustable from the exterior

Precise response

No electronic limiting necessary

Various gear reductions available

Oversized helically geared gearbox

Button

Slide title

Chain

Surface-hardened, galvanised and large dimensioned load chain

High case depth for long service life

High ISO classification according to FEM/ISO standards

Stainless steel or blackened manganesephosphated load chains are available as option

Button

Slide title

WChain box

Large selection of chain boxes in plastic, sheet steel, textile or stainless steel

Available without chain box as an option

Button

Options and features

Although they are already first-class in their standard design, you can make the hoists even safer, more economical and more convenient with a range of mechanical, electrical and electronic options. They simultaneously improve performance, prolong service life and make it possible to adapt the hoist individually to specific requirements.

Here are some of the options frequently used.

Slide title

Control pendant

Robust control pendant with EMERGENCY STOP palm button and control cable

All switching elements for hoist, cross, and long travel are 2-step

IP65 protection

Additional buttons, such as horn activation, can be easily fitted

Button

Slide title

Radio remote control units

Flex-Wave pushbutton unit with protective cover and carry strap

VUE pushbutton units with feedback display

MLTX2 joystick transmitter with controller and carry strap

Optional battery chargers with standard rechargeable batteries

Robust, fibre-reinforced plastic housing, IP66 protection

Frequency ranges 433, 863 or 2,400 kHz

Also available in explosion-proof version

Other radio remote control units optionally available on request

Button

Slide title

SMC Multicontroller

Continuous load monitoring by overload cut-off even if hoist is idling

Overload protection with ALC automatic load control

Load spectrum memory for load-related operating time summation

Operating data registration, e.g. operating hours, load spectrum, motor switching operations and load cycles

Data exchange with PC possible

Button

Slide title

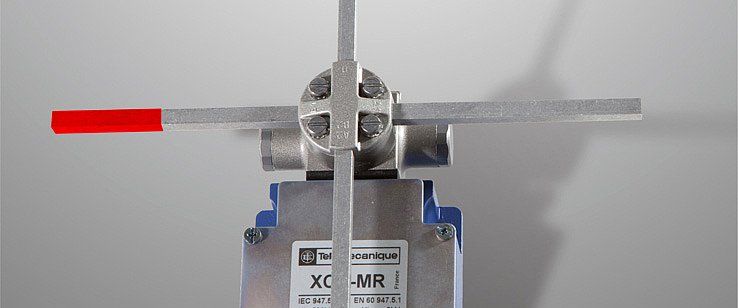

Travel limit switch

Travel limit switch on crab available as option

Limiting for both directions of travel

Switchover from “fast/slow” (predisconnect)

Switch contacts designed for control current

IP66 protection

Button

Slide title

Operational hoist limit switch

Two versions are possible: cut-off in top hook position or cut-off in top and bottom hook position (stationary, push trolley, electric trolley)

Activated by the bottom hook block

Button

Slide title

Gear-type limit switch

Various functions possible: e. g. routine operational cut-off in highest or lowest hook position or switching from “fast” to “slow” before the stops

IP55 protection, optionally IP66

Button

Slide title

Spring-steel chain guide

Heavy high-tensile chain guide for rugged use

Enclosed chain guide

Extremely wear-resistant case-hardened chain sprocket

Button

Slide title

Bypass brake

Second brake for increased safety

Identically dimensioned

Second brake acts in force transmission directly on the load, i. e. bypassed the slipping clutch

As an alternative to the bypass brake, a second hoist motor brake is available

Button

Slide title

Write your caption hereLoad display

SLD four-digit 7-segment load display, large format, luminous red

Available with various interfaces including CAN

Choice of 100 or 150 mm digit height

Combinable with the hoist’s overload sensor and the SMC multicontroller available as an option, no additional fixtures or load attachment devices are required, the headroom of the hoist remains unchanged

Button

Slide title

FMD1 slipping clutch test device

Robust full metal design

Modern electronic test apparatus with field-proven sensor technology, high degree of accuracy ± 2 %

Test range up to 4,000 kg on one chain fall, suitable for chains up to 11.3 mm link thickness

Optionally available for STD and STK

Protector for evaluation device and internal test program

Simple intuitive handling

Button

Download

Brochure

Useful links

Contact info

Phone: +27 (0)83 326 8728

Email: sales@stahlcranes.co.za

Address: 34 Potgieter steet , Alrode ,Alberton

Join the Newsletter

We will get back to you as soon as possible

Please try again later

All Rights Reserved | Stahl Cranes | Privacy Policy | She Policy