SH Wire Rope Hoist

The Tried And Tested All-Rounder

The

SH wire rope hoist programme is used around the world in many different applications. Compact, strong, particularly maintenance-friendly and an ideal when it comes to combining quality, flexibility and performance.

The module system enables almost unlimited combinations of the components. Coming in five sizes with 26 S.W.L. variants, the SH series covers the safe working load range from 500 kg to 25,000 kg. The new SH 6080 wire rope hoist extends the versatile

SH wire rope hoist

range to safe working loads up to 32,000 kg. The

wire rope hoists can be used in stationary applications or together with trolleys in standard cranes, off-standard cranes or systems building.

If wanted, the complete wire rope hoist programme is also available in explosion-proof design for Zone 1, Zone 2, Zone 21 or Zone 22.

- 5 sizes, 26 S.W.L. variants

- Stationary version or various trolleys for cranes and systems building

- Compact size thanks to U-shape

- Largely maintenance-free, low wear, long service life according to FEM/ISO standards

- Standard series with two lifting and two travel speeds

- Particularly soft starting and braking

- Standard series with high-quality safety components for improved work safety

- Optionally available in explosion-proof design according to ATEX and IECEx

Slide title

The particularly soft start of the SH wire rope hoist enables safe transport of bulky loads.

Button

Slide title

The SH wire rope hoist can also be used without problem under difficult conditions because its compact dimensions thanks to its U-shape permit countless possibilities of combination.

Button

Slide title

Additional equipment such as special controls or safety spacers enable individual custom solutions.

Button

Slide title

Special finishes make it possible to also use the SH wire rope hoist outdoors or in corrosive environments.

Button

Slide title

A special controller sees to synchronisation of the cranes and ensures the safety of the complete system when a hoist stops. The four linkable SH wire rope hoists communicate via a modern radio system.

Button

Slide title

Two SH wire rope hoists with separately controllable special load hooks enable lifting and turning of paper reels without lifting beam.

Button

Slide title

Thanks to a double-grooved rope drum, the rope can be guided exactly without lateral hook movement.

Button

Slide title

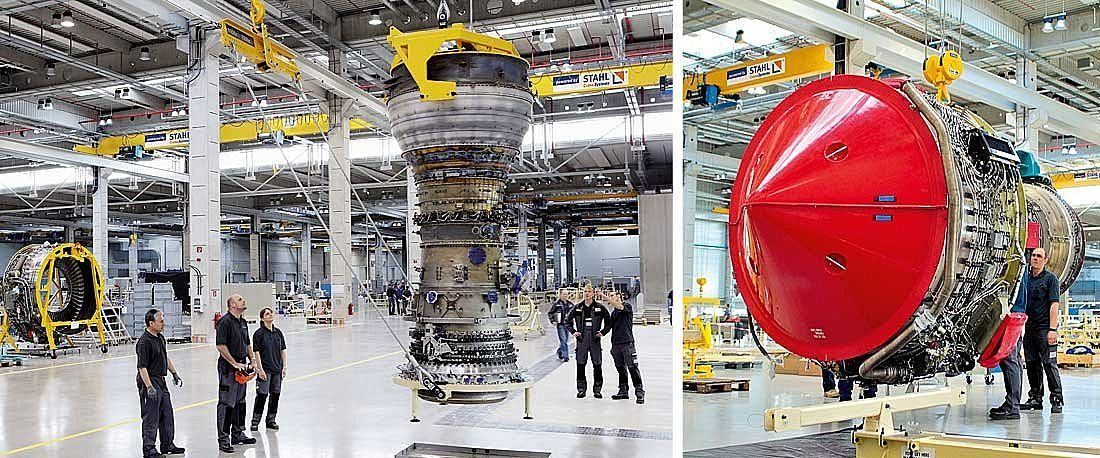

Frequency-controlled SHF wire rope hoists work without lateral hook movement and with extremely little swinging of the load, making them ideal for sensitive loads such as jet engines.

Button

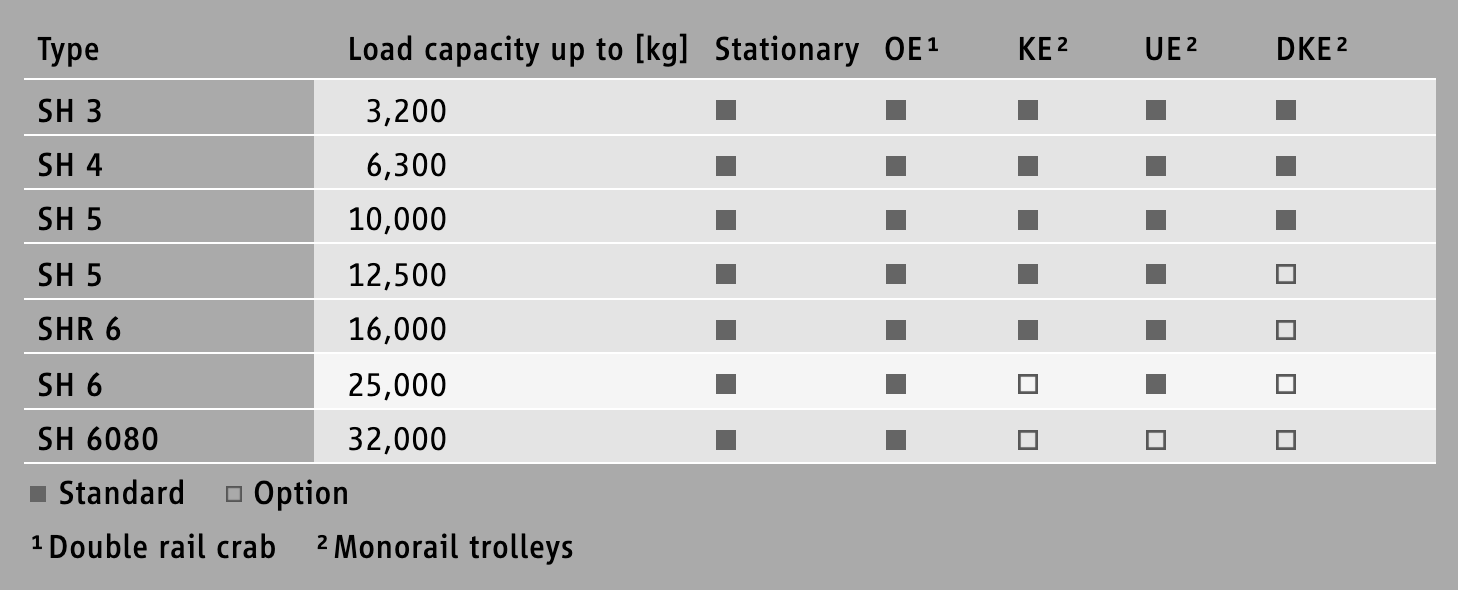

Models

The different models and trolley variants allow not only a wide variety of uses, but also very individualised solutions tailored to specific requirements.

Slide title

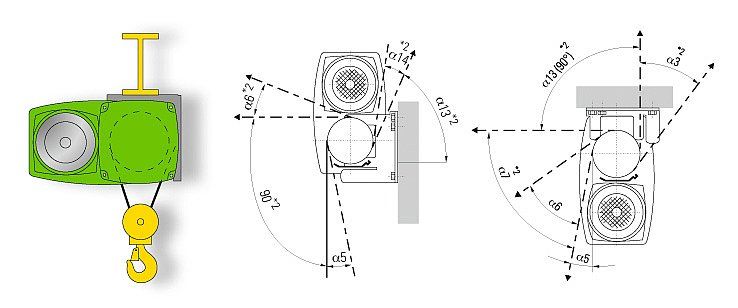

Stationary model

The SH wire rope hoist can be used as stationary hoisting or towing equipment, for example in systems manufacture. Depending on the application, the rope lead-off angle, the attachment of the hoist and the mounting position of the hoist motor can be varied.

Button

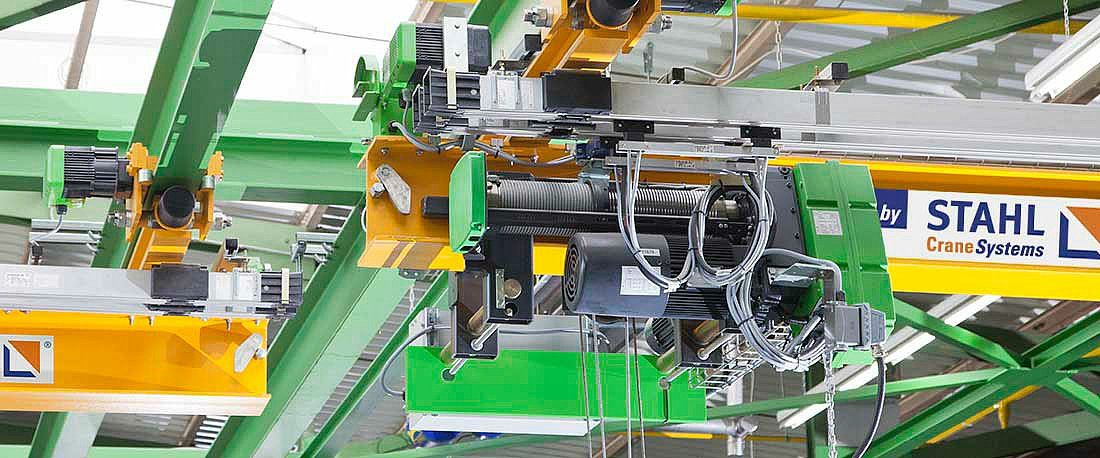

Slide title

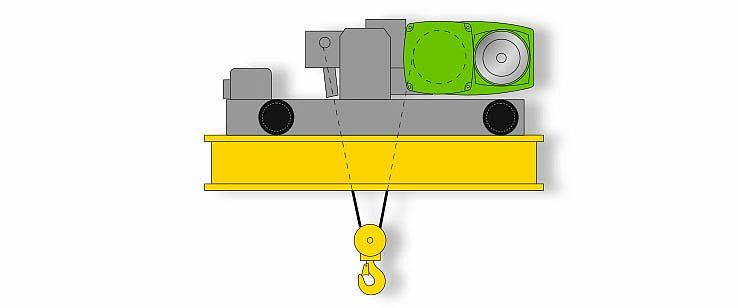

OE double rail crab

The OE double rail crab is intended for use on double girder overhead travelling cranes. The extremely compact construction makes very low approach and headroom dimensions possible and the available space can thus be used to the full. The double rail crab is available with various track gauges for the whole load capacity range and automatically compensates for any unevenness of the cross travel runway.

Button

Slide title

KE monorail trolley

The KE monorail trolley is used on monorail runways and single girder overhead travelling cranes. The particularly low headroom of the trolley makes long hook paths possible even in low-ceilinged rooms.

Button

Slide title

UE monorail trolley

The overall width of the UE monorail trolley is minimal and especially designed for narrow clearances. It is used on monorail runways and single girder overhead travelling cranes.

Button

Slide title

DKE articulated trolley

The DKE articulated trolley is available for frequent travel around bends and narrow radii. Depending on radius of bend, runway flange width or application, it is equipped with one or two travel motors. The side guide rollers work with minimal wear. The DKE articulated trolley is designed for load capacities up to 10,000 kg.

Button

Slide title

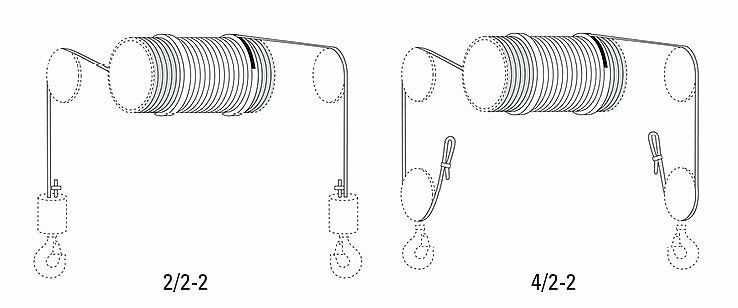

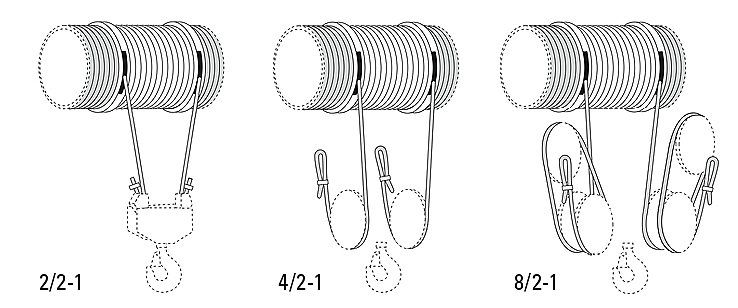

Single-grooved rope drum (Standard reeving)

The model with single-grooved rope drum is used for stationary hoisting or towing equipment or combined with various travel carriage variants.

Button

Slide title

Double-grooved rope drum (True vertical lift)

If true vertical lift is required, we recommend this model with double-grooved rope drum (right-/left-hand thread). This version can be used both in stationary form or with travel carriages.

Button

Slide title

Double-grooved rope drum (Reeving for multiple load pick-up points)

The model with double-grooved rope drum (right-/left-hand thread) is used for many lifting and towing tasks where the load must be picked up at more than one point and true vertical lift is required.

Button

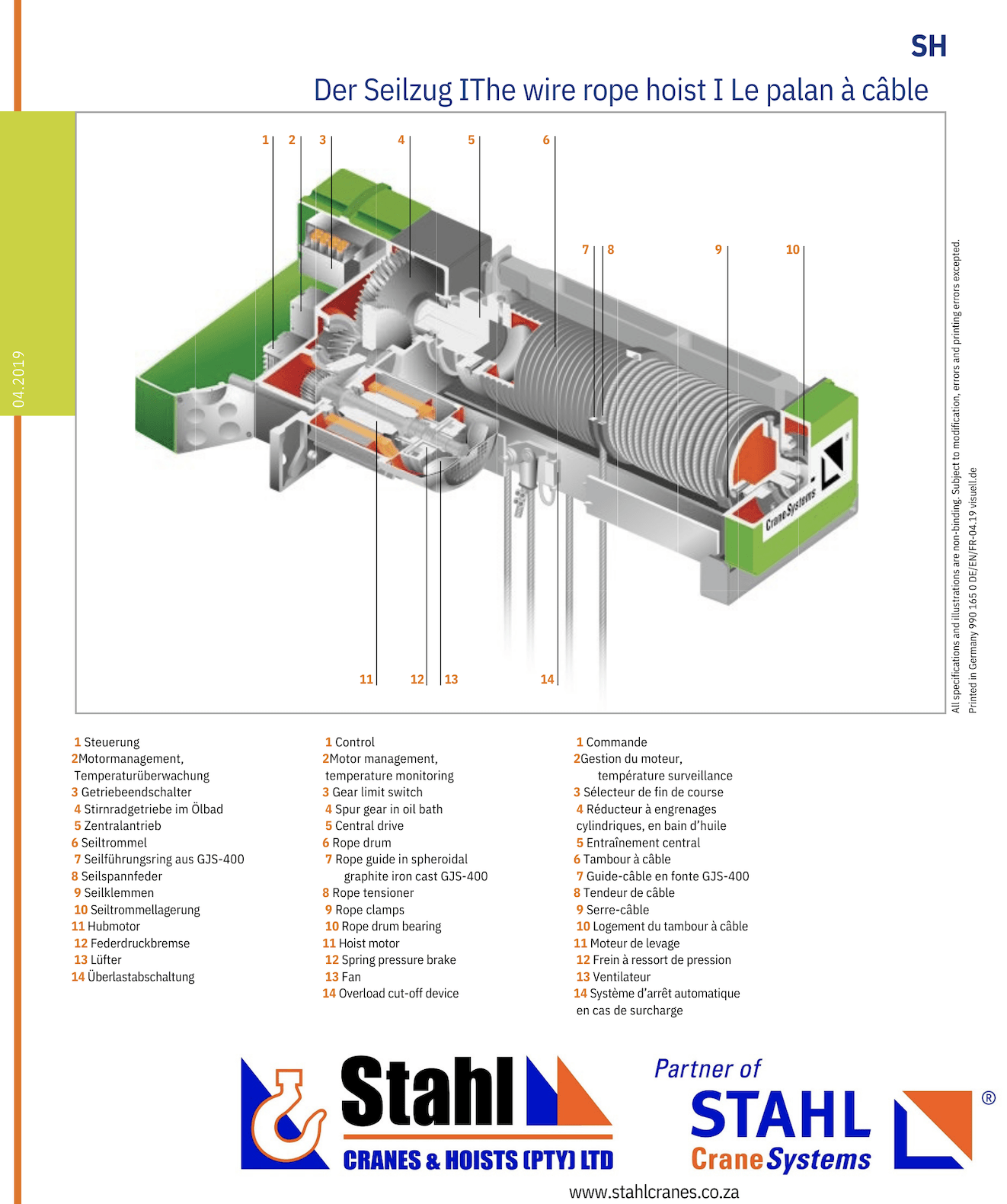

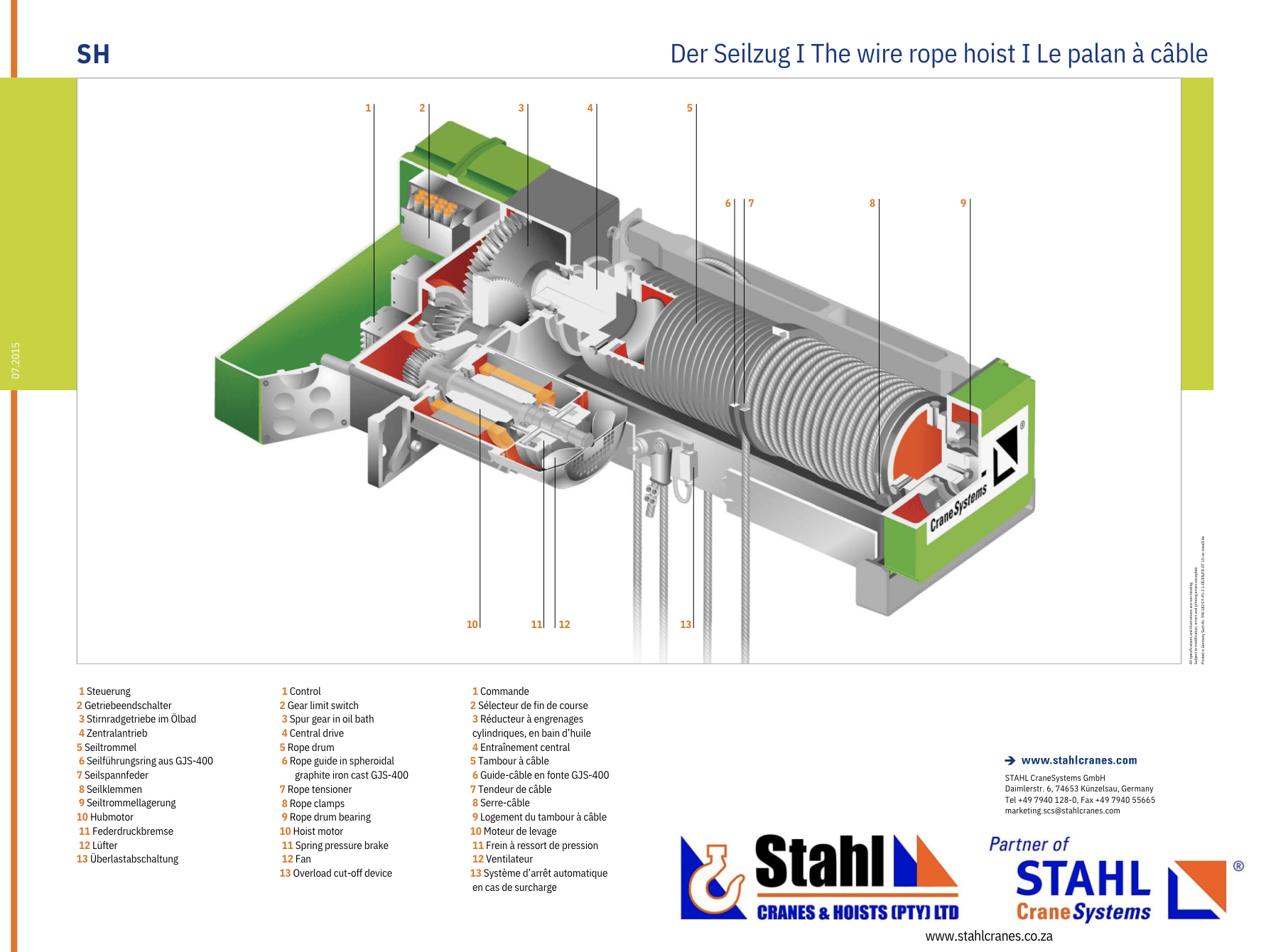

Technology

Slide title

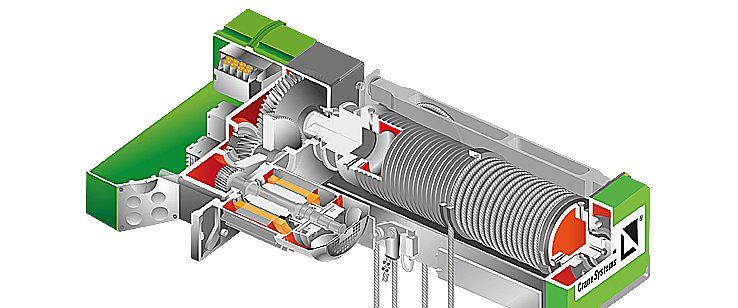

The SH wire rope hoist programme boasts superior technology. The largely maintenance-free components of the modular wire rope hoist are matched to each other optimally. They guarantee constant performance, long service life and high efficiency.

Button

Slide title

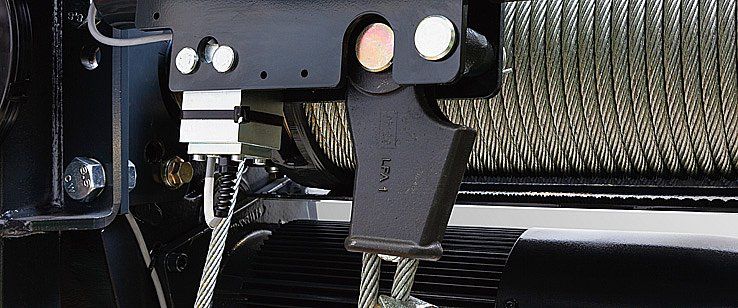

Rope and rope guide

Highly flexible special rope with long service life

Field-proven enclosed rope guide in spheroidal graphite cast iron has no temperature limitations

The GJS material (previously designated GGG 40) is suitable for highest and lowest temperature ranges

360° rope tensioner prevents the formation of rope slack

Button

Slide title

Paint

Standard paint treatment as per RAL 6018 yellow-green and RAL 7021 black grey

High-quality primer and top coats for standard applications

Off-standard paint treatment for outdoor use or corrosive ambient conditions

Shade as per customer’s requirement

Button

Slide title

Overload cut-off

Permanent electronic monitoring of the suspended loads

Limitation of the maximum load by load measurement at the rope anchorage possible in the case of multiple reeving

Button

Slide title

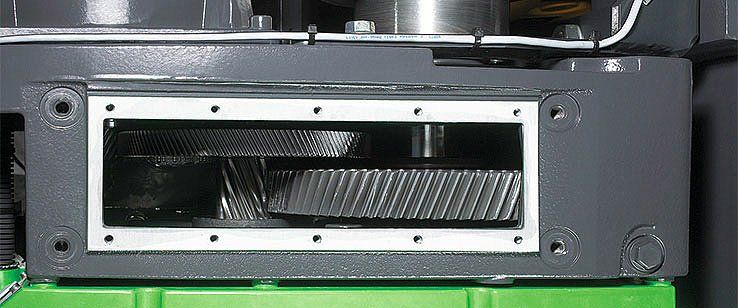

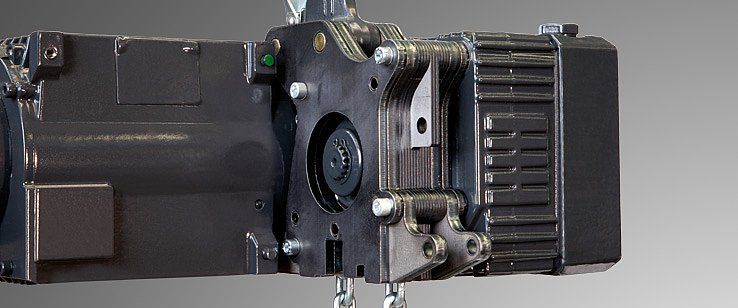

Hoist gear

All gear stages with lifetime lubrication in oil bath

Modern technology ensures quiet operation

Button

Slide title

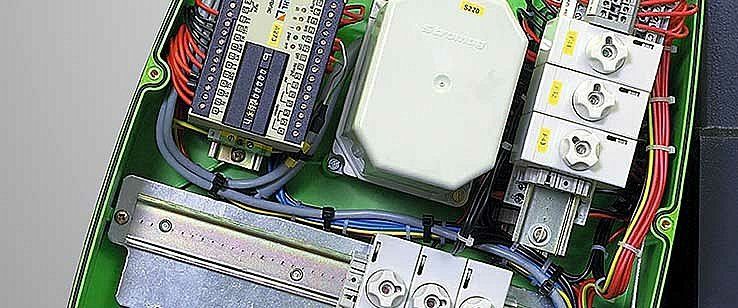

SLE/SMC control and motor management

Condition monitoring as standard

Inching operation is suppressed to reduce stress on equipment

All common control voltages available

High degree of safety due to oversized contactors

Temperature monitoring of the hoist motor and travel motor

Button

Slide title

Brake

Low-maintenance, asbestos-free brake needs no adjustment

Long service life thanks to oversized brake

Brake easily accessible for inspection from outside

Motor management ensures low wear

IP65 protection, IP66 optional

Button

Slide title

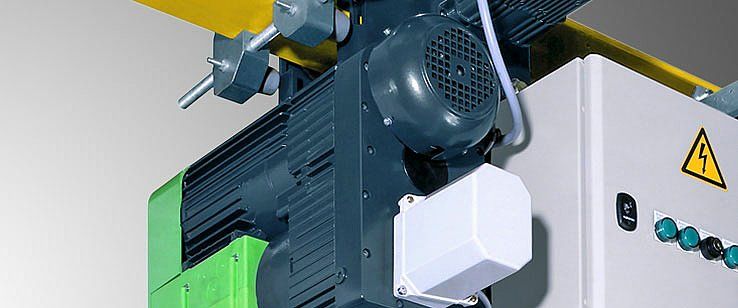

Motor

Special-purpose motor for hoisting applications

Classification according to FEM/ISO standards, high-duty-cycle and switching operation frequency motor

IP55 protection, IP66 optional, thermal class F

Motor outside rope drum, highly efficient motor cooling, maintenance-friendly

Temperature control by PTC thermistors

Button

Slide title

Rope drive

Optimised ratio of drum-to-sheave diameter ensures low wear on rope

Flexible and long-lasting wire rope

Wear-resistant return sheaves, fine machining provides rope-friendly grooves in rope drum

Drum easily accessible for rope replacement

Robust bottom hook block with low headroom in spite of large dimensioning of hook

Button

Options and features

Although they are already first-class in their standard design, you can make the hoists even safer, more economical and more convenient with a range of mechanical, electrical and electronic options. They simultaneously improve performance, prolong service life and make it possible to adapt the hoist individually to specific requirements.

Here are some of the options frequently used.

Slide title

Control pendant

Robust control pendant with EMERGENCY STOP palm button and control cable

All switching elements for hoist, cross, and long travel are 2-step

IP65 protection

Additional buttons, such as horn activation, can be easily fitted

Button

Slide title

Radio remote control units

Flex-Wave pushbutton unit with protective cover and carry strap

VUE pushbutton units with feedback display

MLTX2 joystick transmitter with controller and carry strap

Optional battery chargers with standard rechargeable batteries

Robust, fibre-reinforced plastic housing, IP66 protection

Frequency ranges 433, 863 or 2,400 kHz

Also available in explosion-proof version

Other radio remote control units optionally available on request

Button

Slide title

SMC Multicontroller

Continuous load monitoring by overload cut-off even if hoist is idling

Overload protection with ALC automatic load control

Load spectrum memory for load-related operating time summation

Operating data registration, e.g. operating hours, load spectrum, motor switching operations and load cycles

Data exchange with PC possible

Button

Slide title

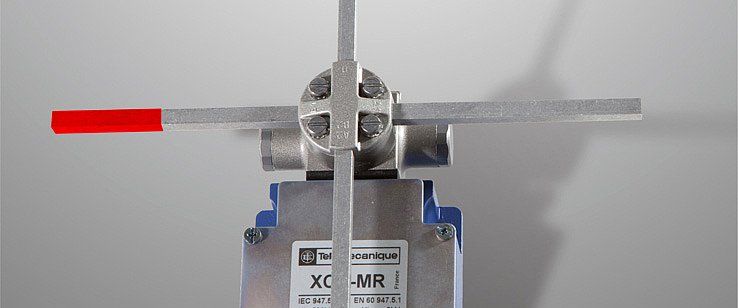

Travel limit switch

Travel limit switch on crab available as option

Limiting for both directions of travel

Switchover from “fast/slow” (predisconnect)

Switch contacts designed for control current

IP66 protection

Button

Slide title

Operational hoist limit switch

Two versions are possible: cut-off in top hook position or cut-off in top and bottom hook position (stationary, push trolley, electric trolley)

Activated by the bottom hook block

Button

Slide title

Gear-type limit switch

Various functions possible: e. g. routine operational cut-off in highest or lowest hook position or switching from “fast” to “slow” before the stops

IP55 protection, optionally IP66

Button

Slide title

Spring-steel chain guide

Heavy high-tensile chain guide for rugged use

Enclosed chain guide

Extremely wear-resistant case-hardened chain sprocket

Button

Slide title

Bypass brake

Second brake for increased safety

Identically dimensioned

Second brake acts in force transmission directly on the load, i. e. bypassed the slipping clutch

As an alternative to the bypass brake, a second hoist motor brake is available

Button

Slide title

Write your caption hereLoad display

SLD four-digit 7-segment load display, large format, luminous red

Available with various interfaces including CAN

Choice of 100 or 150 mm digit height

Combinable with the hoist’s overload sensor and the SMC multicontroller available as an option, no additional fixtures or load attachment devices are required, the headroom of the hoist remains unchanged

Button

Slide title

FMD1 slipping clutch test device

Robust full metal design

Modern electronic test apparatus with field-proven sensor technology, high degree of accuracy ± 2 %

Test range up to 4,000 kg on one chain fall, suitable for chains up to 11.3 mm link thickness

Optionally available for STD and STK

Protector for evaluation device and internal test program

Simple intuitive handling

Button

Download

Brochure

The SH wire rope hoist

Poster

The wire rope hoist SH

Useful links

Contact info

Phone: +27 (0)83 326 8728

Email: sales@stahlcranes.co.za

Address: 34 Potgieter steet , Alrode ,Alberton

Join the Newsletter

We will get back to you as soon as possible

Please try again later

All Rights Reserved | Stahl Cranes | Privacy Policy | She Policy