Chain Block Checklist.

Selecting The Right Chain Block for your company.

Selecting the correct chain block (also known as a chain hoists) for your application can be a confusing task. We’ve compiled the list below to help answer your question, “How do I select a chain hoist“, or “What kind of chain hoist do I need?“.

Manual and electric chain blocks are used for a variety of lifting reasons. The how to checklist below is going to help simplify which hoist will work best for you and your application.

Capacity: First we’ll need to know the weight of whatever it is you are picking up? Once we have this number we will round up to the nearest 1/4 ton, 1/2 ton, or ton. Depending on the manufacturer, the 1/4 ton and 1/2 ton increments will usually stop being offered after 3 tons of capacity. What does this mean for you? If your load is just over 3 tons in weight (6,000 lbs), you may have to upgrade to a 4 Ton chain hoist to ensure a safe pick and proper functioning of your new chain hoist.

Lift: Next we’ll need to determine the amount of lift your application requires. To determine lift you will need to know two critical pieces of information. First, where will your chain hoist hang from; and secondly where will the load to be picked be located in relation to the chain hoist. Finding your lift number will be nothing more than subtracting the resting location of the item to be picked from the hanging location of the hoist. For example, if your item to be picked is located on the factory floor, and the beam the chain hoist sits on is at a height of 22 feet, then you will need at least 22 feet of chain lift with your new hoist. When in doubt, always add a couple feet of lift to be safe; chain is sold by the foot and it can not be added to the existing chain.

Speed: Next we’ll need to determine the speed in which you would like to lift your item. This can be a tough decision to make for someone who does not have a lot of experience with lifting, and may best be left to a professional to answer. Traditional speeds can range from just a couple (2 or 3) feet per minute to 16 and 32 feet per minute.

Incoming Power: Next we need to determine your power source. If you will be using single phase power, you will have to determine if the volt supply is 115 (what we find in our homes) or 230 (what our home dryers plug in to and often found in small machine and carpentry shops). Larger factories and industrial workplaces will usually be running on three phase power; three phase voltages range from 208, 230, 460, and 575. If you do not have this information, you should reach out to your power supply company; choosing the wrong voltage can instantly fry your new hoist, costing you thousands of dollars in replacement costs before you even get to use it.

Control Voltage: In line with the above question, you will need to determine which control voltage you prefer to send to the handheld pendant. This is usually one of two options, 115 volt or 24 volt. If possible, 24 volt is the desired option for safety.

Pendant Control Cable Length

The pendant control cable length is known as “push button drop” in the lifting industry. This is how far down from the chain hoist you would like the hand control to hang in the air. Standard push button drop is equal to 4 feet less than the lift. Using the example above, if you have 22 feet of lift, the standard hand pendant or push button drop will be 18 feet below the chain hoist, or 4 feet above the floor in this application.

Type of Suspension

Next we will discuss how the chain hoist will be suspended. There are two common options for suspending or hanging a chain hoist, Hook mount or Lug mount. With Hook mount, the chain hoist will come from the factory with a hook attached to the top of the body. This hook will rest inside an opening on the trolley, a rolling device that rests on the Beam (explained in greater detail below). There are two common types of hooks available, rigid and swivel. The rigid hook is just as it sounds, it does not swivel and therefore the chain hoist can not rotate 360 degrees on the trolley as in the case with a “swivel” hook. The swivel hook is also just as it sounds, allowing for the chain block to spin clockwise or counterclockwise during operation.

Type of Trolley

There are a few different options when choosing a trolley, but first lets define what a trolley is. A trolley is a device that rests and rolls along the Beam your chain hoist will operate from. There are 3 common types of trolleys, we will discuss all three below.

Plain Trolley: Also known as a push/pull trolley, a plain trolley is the simplest form of trolley available. As discussed above, the hoist will hang from this trolley by either a hook or lug mount. A plain trolley will move the chain block along the Beam by human power via the hoist operator. The operator will grab either the hook or the item being lifted and pull or push the item to move it in the desired direction along the Beam.

Geared Trolley: A geared trolley is the next step up in ergonomics. With this option, the chain hoist operator will pull on a chain hanging from the trolley (much like a manual overhead door operator), and the trolley will use it’s gears to roll the trolley wheels along the Beam instead of human push/pull power as we discussed with the plain trolley. When ordering a geared trolley, one must specify the hand chain drop required. Standard hand chain drop is 4′ less than lift, similar to the pendant station or push button drop we discussed earlier.

Motorised Trolley: The motorised trolley option is the most ergonomic of all the options we’ve covered. This option is exactly what it sounds like, instead of a plain push/pull trolley, or manual geared trolley, this trolley will have a motor attached to the side of the trolley wheels. A motorised trolley can have it’s own control pendant that will hang down from the beam in close proximity to the chain hoist pendant. A trolley speed must be specified when ordering a motorised trolley. Industry standards are 35 fpm and 75 fpm, but accommodations can be made for fragile, or sensitive loads that require a little more finesse.

Type of Beam

There are three common types of beams in which we can use to hang a hoist. Correctly identifying your type of beam is imperative to ensuring your chosen trolley will operate and roll properly.

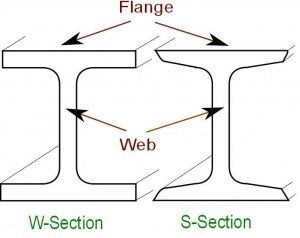

I-Beam: An I-beam, also known as H-beam, W-beam or WF-beam (for “wide flange”), is a beam with an I- or H-shaped cross-section. The horizontal elements of the “I” are flanges, while the vertical element is the web. The web resists shear forces while the flanges resist most of the bending moment experienced by the beam. Beam theory shows that the I-shaped section is a very efficient form for carrying both bending and shear loads in the plane of the web.

WF-Beam: Also known as a Wide-Flange Beam is the most common I-beam found. A Wide-Flange beam have flanges in which the planes are nearly parallel; unlike the “S” style beam which has a tapered flange.

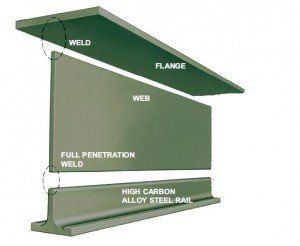

Patented Track: A patented track beam is similar in conception to the standard S and WF I-Beam with one significant difference; The bottom flange of a patented track has a 3.25″ wide flange made of specially hardened steel with a raised lip to form a perfect rolling surface. The specially hardened bottom flange is then welded to the upper portion of the beam.

Patented Track beams are generally more expensive than the other two options, however the buyer also gets what they pay for, an extremely rugged beam meant for harsh repetitive environments where precision and consistency is of the utmost importance. Many military facilities and aircraft maintenance hangers will rely upon the Patented Track.

When purchasing your hoist, it is imperative that you inform your hoist distributor of the beam height, flange width, and the degree of taper if dealing with a “S” style I-Beam.

Useful links

Contact info

Phone: +27 (0)83 326 8728

Email: sales@stahlcranes.co.za

Address: 34 Potgieter steet , Alrode ,Alberton

Join the Newsletter

We will get back to you as soon as possible

Please try again later

All Rights Reserved | Stahl Cranes | Privacy Policy | She Policy